Any capital structure - a private house, garage, multi-storey building, cottage or other structure is designed in such a way that the foundation can withstand its high load. However, in addition to this, it should be remembered that the basement of the house must be reliably protected from the aggressive effects of moisture., which, when penetrating inside, significantly reduces the strength of the base and often causes subsidence of the structure. Properly executed cladding of the basement of the house, on the one hand, reliably protects the foundation from influences (including physical ones), and on the other hand, gives the building a more beautiful look.

Why is plinth cladding necessary?

Many owners of private houses and cottages consider the exterior lining of the basement only as an element of exterior decoration, trying to make it more beautiful and refined. The desire is quite understandable - the beautiful decoration of the lower part of the building gives the whole structure a qualitatively new look, makes it distinguishable from other houses, and shows the artistic taste of the owners.

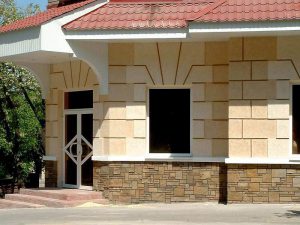

Facing the basement of the house with natural stone

However, it should be remembered that the main tasks of facing include:

1. Protection of the base of the building from ultraviolet radiation, weathering, sudden changes in temperature, high humidity, direct sunlight (leading to heating)

Basement cladding will protect the house from moisture

2. Counteraction to various pollution. The lower part of the house is almost always exposed to dust and dirt, all kinds of chemically active substances that cause erosion even in the most resistant concrete.

Plinth cladding will prevent concrete erosion

3. Protection against the possible penetration of the pores of fungus and mold, other biological life that can cause significant harm to the building and the health of people living in it.

Facing will not allow mold to penetrate

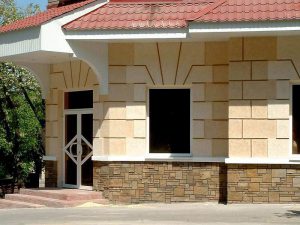

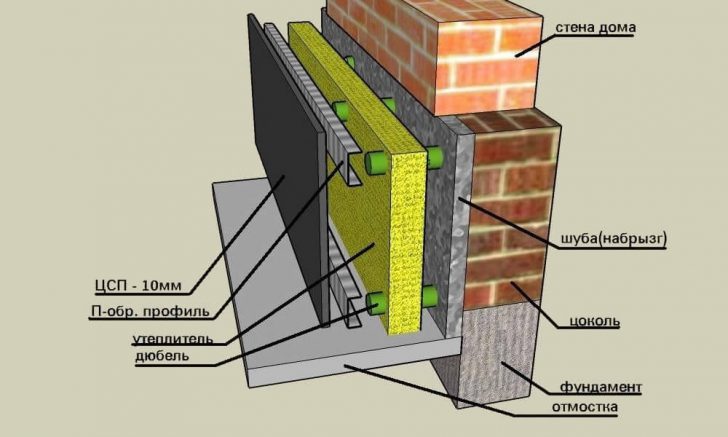

4. The ability to pre-insulate the basement, preventing cold from entering the lower rooms through the concrete

House basement insulation scheme

Based on the foregoing, they conclude: any basement, regardless of the type of building, needs effective protection, therefore, when building a structure, the project necessarily provides for such a finish. To select the appropriate option, a person learns the characteristics of the material and its scope.

back to index ↑Wide variety of finishing materials

Today, there are a lot of materials used for high-quality finishing of the base, and each of them has its own characteristics and properties. Below we will consider those that are most common in modern construction:

1. Plastering with cement-sand mortar followed by painting.

This is the simplest type of house basement cladding, used in cases where the owner's budget is limited.

House with plastered plinth

A layer of plaster is applied to the surface of the basement, with a thickness of 5 to 10 cm (determined by the project), after drying, the surface is carefully primed (to protect against moisture) and painted.

The scheme of finishing the basement of the house with plaster

The main advantages of this cladding method are:

- Cheapness

- Availability for every owner

- Ease of execution

- Good decorative

Facing the plinth with plaster, a fairly economical option

It should be emphasized that with a good protective layer, such a finish will be vapor-permeable, so all excess moisture will freely leave the house outside, preventing the likelihood of mold. A modification of such a finish is the modeling of stones with a plaster mortar, which is made very thick, as a result of which the effect of finishing the base with a “stone” is quickly and beautifully created. The work requires skills, but with the desire and training, each owner will be able to do this, achieving a good result.

Stone effect plinth plastering

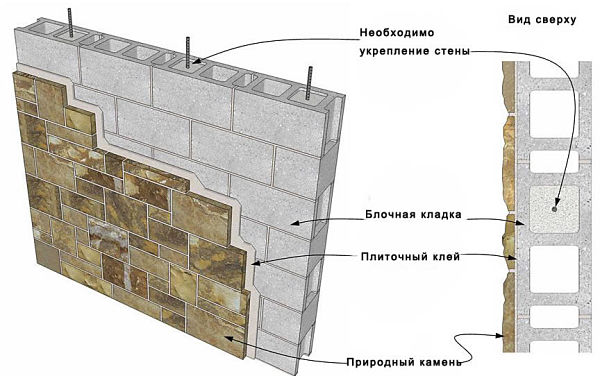

2. Natural stone.

Facing the basement of the house with natural stone has beneficial advantages. The material is natural, has excellent performance and environmental characteristics. Moreover, this finish looks very rich, so it gives the building an elite look, which is always clearly visible from the outside.

Spectacular stone plinth finish

There are many options for such a finish, which is due to a significant variety of finishing materials and components, and the stone is selected from smoothly polished (mirror) to rough and unhewn.

Facing the basement of the house with raw stone

The cladding materials are as follows:

A) Granite stone slabs - slabs having a regular rectangular shape (with even or torn edges), a thickness of 20-30 mm and a convex pattern. Most often used for facing the plinths of large buildings with a powerful and strong foundation. With this finish, it is taken into account that granite slabs have a significant weight, which increases the load on the base of the house. Installation is complex, requires the use of reinforcing mesh and high-strength masonry mortar. The price of granite and marble slabs is quite high, so not all citizens of our country can afford such a lining of the basement of a house.

Plinth cladding with granite slabs

B) Shell rock or limestone. These natural finishes can be chipped or polished, depending on the type of material. Their weight is relatively small, but laying requires professional skills in order to achieve evenness and accuracy, so you can’t do without the help of qualified specialists.

Finishing the basement of the house with limestone

V) Sandstone. This material is the most popular of all natural, has a beauty, yellowish-sand color. Materials can be both in the form of even rectangular tiles, and in the form of irregularly shaped products stacked in a chaotic manner, resulting in an unusual and unique pattern.

Sandstone cladding in a chaotic manner

3. Fake diamond. The modern production of artificial stones has reached such a level that, in their appearance, the lining of the basement of a house with such material is practically no different from natural stone.

Visually, facing with artificial stone is difficult to distinguish from natural

Of the main advantages of artificial finishing material, there are:

- low cost

- Lighter weight than natural stone

- Simplified installation

- Excellent aesthetic qualities due to the uniformity of the plates (color, shape)

Artificial stone is much lighter than natural

Artificial facing stones are made from special cement-containing mixtures with the addition of expanded clay crushed stone, additional plasticizers, micro-reinforcing components and dyes.The liquid fraction is poured into special silicone molds, rammed and hardened in it, exactly repeating the shape of natural stone. After a few days, the material is ready for use. Some products are made by hyper-pressing, with the help of which tiles are obtained, 1.5-2 cm thick.

Production process of artificial stone

Relatively recently, piece sets appeared on the Russian market, formed on the principle of connecting several tiles into a single structure. The linear dimensions of such components can be different, but they are assembled and placed on the adhesive solution according to the principle of the designer, which greatly facilitates installation. The only thing, in this case, the finishing surface should be perfectly aligned over the entire area of \u200b\u200bthe base, which should be given special attention. In some cases, these mounting plates have special steel plates embedded in the plates, due to which the plates adhere to the solution even better.

The technology of finishing the socle with artificial stone

Artificial stones in the form of even tiles of the correct shape are attached with polyurethane adhesive to a rigid base such as OSB board, glass magnesite or fiber cement. In this case, the plinth automatically receives additional insulation, which increases the thermal insulation properties of the building as a whole.

4. Finishing the plinth with bricks. Real brick, laid around the entire perimeter of the building at the basement level, immediately gives the building respectability, but it should be remembered that this entails an additional load on the foundation. For this reason, such a finish is provided at the design stage of the building itself, where the foundation is made stronger and more powerful.

Brick plinth finish is suitable for houses with a strong foundation

When installing with such a brick, a ventilated space is sometimes left between the wall, or it is filled with additional insulation (polystyrene foam, mineral wool). Here, clinker, gas silicate, clay or hyper-pressed bricks (the heaviest) are used, which already depends on the desire of the customer and the architectural features of the structure.

Facing the basement of the house with bricks

An excellent alternative to real brick can be clinker tiles, which imitate real brickwork with high reliability.

The process of finishing the basement with clinker tiles

Its main advantage is low cost, light weight, ease of installation. For this reason, owners of private houses and cottages most often choose this type of finish, especially since a rich assortment of colors and textures allows you to choose the most suitable one for yourself.

Clinker tiles are lightweight and easy to install

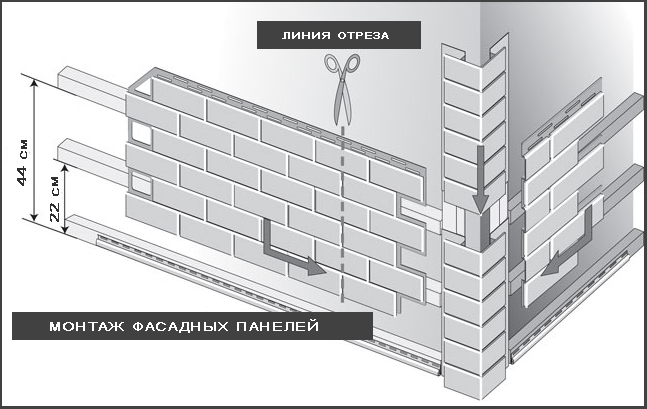

5. Basement siding. These products have confidently taken their place in the market of finishing materials. Their main advantages are lightness in weight, ease of fastening, and not subject to moisture. Most often they are made of polyvinyl chloride (PVC), and they can have a wide variety of colors and even a texture that imitates stone or brick.

Plinth cladding with practical plinth siding

Of the features of such systems, they are distinguished by the fact that they are mounted on a pre-installed subsystem and most often have internal insulation.

Basement siding installation scheme

Basement siding, used as an advantageous cladding of a house, has a significant advantage, it can have not only a traditional “stony” structure, but also be made under a rounded beam of the block house type. The cost of such elements in comparison with other finishing materials is quite adequate, therefore, many owners confidently prefer such a finish when decorating their homes.

Socle siding for round timber

Installation of ebbs is an important element in protecting the basement

As a rule, the plinth of the building extends slightly beyond the walls, therefore, during heavy rains, water sometimes seeps into the space between the finishing material and the wall, causing destruction of both the wall and the finishing material. To prevent this from happening, experienced builders must install the ebb, which is made of galvanized steel, followed by the application of a polymer coating.

Galvanized steel drip tray over plinth

An exclusive option is copper sills, which give the building a more beautiful look, but are extremely expensive and only wealthy citizens of our country can afford them.

Copper plinth

Conclusions on the basement finish

Summing up, they note that high-quality and properly executed cladding of the basement of the house allows, on the one hand, to give the building exclusivity and beauty, and on the other hand, to reliably protect the foundation from destruction. Given the particular complexity of performing such work, it is best to entrust it to specialists with experience. Of course, when choosing a material, attention is paid to its quality, because the constant impact of aggressive factors in the form of rain, snow, sudden changes in temperature, humidity and frost make serious demands on the material.

back to index ↑Photo gallery - facing the basement of the house

Video