Going out into nature is always a lot of fun. Fresh air combined with delicious food cooked over a live fire and pleasant conversation is the best way to take a break from the daily routine. The brazier is really the main attribute of a country picnic.

Today, this comfort accessory is not a problem to buy, however, barbecue lovers from this step are stopped by the quality of the proposed product range. Basically, all the models put up for sale are made of too thin material, and the very first “barbecue season” becomes fatal for them.

Finished metal brazier

If you want to get a friend for decades - try to go the other way and make a metal grill with your own hands. This is a great way to get a more solid, and sometimes even exclusive version of the brazier, which, moreover, can be fully adapted to your needs. "Homemade" can look standard or become a highlight of the decor of a summer cottage, and this is already an occasion to get acquainted with the types and production process of metal structures for frying kebabs closer.

back to index ↑Types of metal grills

First of all, these products are divided by overall parameters. Mangal can be done:

1. Stationary.

Stationary brazier made of metal with a canopy

2. Portable.

Lightweight portable brazier made of metal

Each of the points can also be interpreted in different ways. Stationary types are divided into:

- on traditional barbecues;

Classic stationary brazier made of metal

- art deco designs.

Barbecue made of metal in art deco style

Portable can be:

- folding;

Portable folding grill

- collapsible.

Collapsible brazier made of metal

But in parallel, both options can be a barbecue, both stationary and mobile.

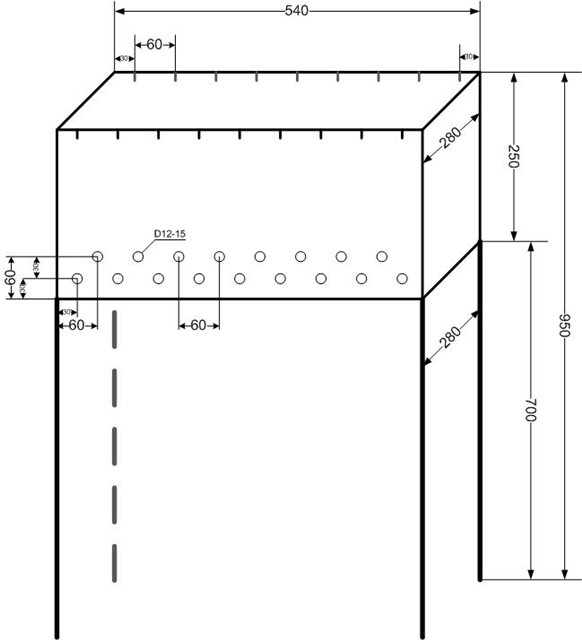

Stationary brazier is the prerogative of suburban areas. Often they combine metal with masonry, thus adding aesthetics to the appearance and making the structure more functional. By installing a brazier under a canopy or by equipping it with a roof, you will be able to cook food in any weather.

Combined brazier made of metal and stone with a roof

Portable models are seductive in that they can be installed not only anywhere in the suburban area, but also taken with them on a hike, and even on foot, as they are small in size and insignificant in weight. A folding version of the barbecue made of metal can be made with your own hands so compactly transforming that it will resemble a small suitcase.

Metal grill that folds into a suitcase

The simplest model of the brazier is represented by two metal frames that serve and support the skewers.

The design of a simple barbecue

The main advantage of folding braziers is also their disadvantage. Excessive compactness does not allow you to cook barbecue in large quantities, so for a solid company it is better to take two portable braziers with you at once.

If you don’t plan to wear a brazier manually, then you can make a heavier structure by supplementing it with a retractable table top, gratings and arranging an adjustable blower in it.

Barbecue made of metal with a wooden top

In order to turn the brazier into a barbecue, it is enough to install a grill grid over the brazier. The latter are rectangular and in the shape of a hemisphere, so choosing the right model for the barbecue will not be a problem. If you don't like crispy meat, upgrade your BBQ with a regular lid.

Barbecue with a grill grate

Products of the Art Deco series are assembled from forged elements. The latter can be the basis of the structure or its decorative part. Mostly, forging is found in stationary versions, as it is heavy and massive. It will be difficult to transport such a brazier, except to put it on wheels, transforming it into a car trailer.

Forged brazier in Art Deco style with wheels

The basic design of the brazier made of metal can be modified with your own hands, that is, equipped with additional modules in the form of:

1. Wheels.

2. Roofs.

3. Stands and shelves.

4. Double braziers.

5. Pens.

Brazier made of metal with additional shelves

However, this should be done only if you cannot do without these elements. It must be remembered that each of the presented additions will add weight to the design. This rule is written for portable models. Stationary braziers have no restrictions in this regard.

Braziers can be classified based on such an indicator as the thickness of the metal. In this classification, they will be divided into:

- on thick-walled;

Thick-walled barbecue

- thin-walled.

Thin-walled metal brazier

Thick metal is usually used for stationary barbecue models. A brazier for them can be made from steel sheets of 5 or more millimeters. You will have to spend a little money, but it will serve you for a very long time.

Thick-walled stationary brazier

For portable options for braziers, you need to take metal of a smaller thickness. This is one of the ways to lighten the design, because you remember that a situation may arise when you have to carry it with you in your hands for a fairly long distance. In a thin-walled brazier, even from very high-quality metal, it is impossible to burn firewood. Ready-made coals are used here, packages of which can be purchased at the store or prepared on their own, in a fire.

Barbecue made of thin metal

Why are metal grills good?

"To assemble do-it-yourself metal brazier it will take several hours, and upon completion of the work, the finished product can be immediately tested and tested in practice "

The advantages of metal braziers are obvious.

1. They are mobile. It does not matter whether the brazier is disassembled or not, it can be removed for the winter period in a barn. Such care for the design will help to extend its life.

Barbecue made of metal can be removed for the winter

2. Fireproof. This is guaranteed by the material used in the manufacture and the shape of the brazier itself.

3. Relatively cheap. The difference in the cost of materials and work when installing a stone fireplace and a metal one is very significant.

The metal brazier is easily installed in the right place

4. Quickly mounted. It will take at least three weeks to erect a stationary stone brazier, taking into account the technologically provided breaks for the foundation to solidify and the mortar to set. For assembly do-it-yourself metal brazier it will take several hours, and upon completion of the work, the finished product can be immediately tested in practice.

Brazier made of metal on a prepared site

Connoisseurs of capitally equipped structures consider metal braziers, to put it mildly, unaesthetic and nondescript, but it depends on who gets to work. Sometimes real masterpieces come out of the hands of our "Kulibins".We will describe several interesting ideas from the “crazy hands” series below, and now we will deal with the sequence of the process of working on an ordinary, familiar barbecue.

back to index ↑How to assemble a brazier with your own hands

Those who are familiar with metal firsthand will not need advice and guidance. Professionals will assemble the structure with their eyes closed. But beginners in this field will have a hard time. In order for the first experience to be positive, it is necessary to approach the process of creation thoroughly and slowly. Do not start with abstruse models. Let your "first-born" be ridiculously simple in a decorative aspect, but perfectly functioning. Subsequently, having gained experience and improved skills, you can try to create something extraordinary for frying kebabs, but for now your goal is a “box with legs”. Let's go to her.

Such a brazier made of metal is not difficult to make with your own hands.

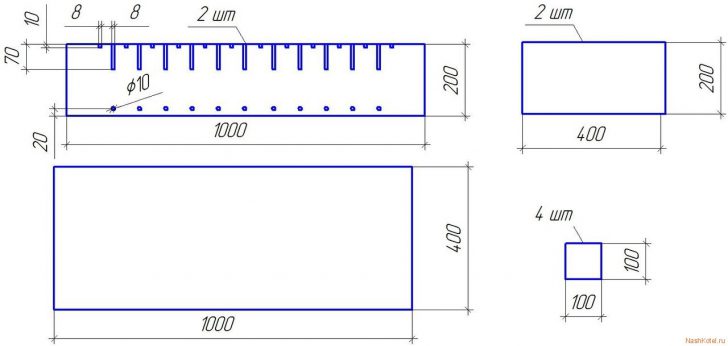

Structural elements

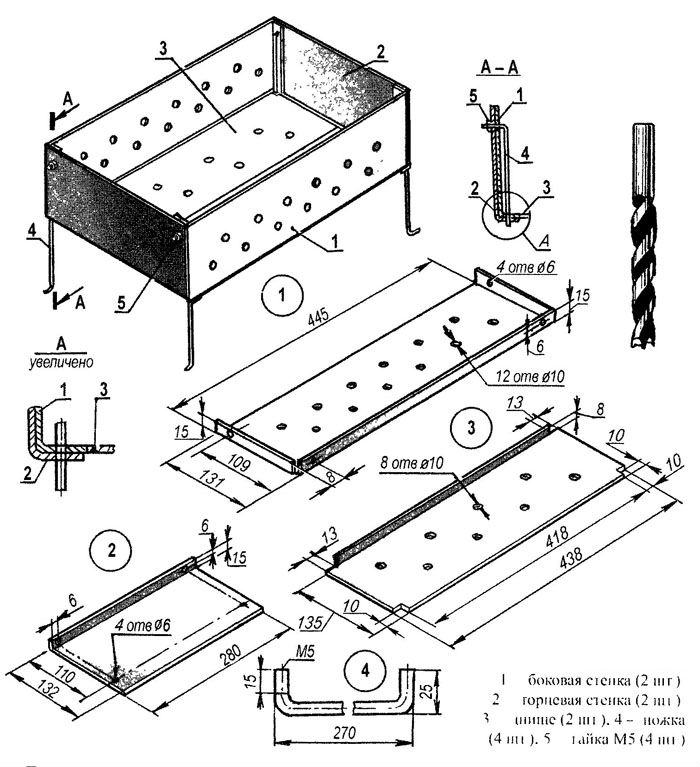

To create a mobile barbecue you need:

1. 4 legs.

2. 4 rectangular perforated walls.

3. Bottom.

Necessary parts for a metal grill

With what and what to work

In order to get the desired parts and assemble them into a functional design, you will need:

- steel sheet;

- metal corner or fittings with nuts and bolts;

- welding machine with spare electrodes;

- hacksaw for metal;

- grinder and cutting wheels for it;

- drill.

To make a brazier with your own hands, you need a welding machine

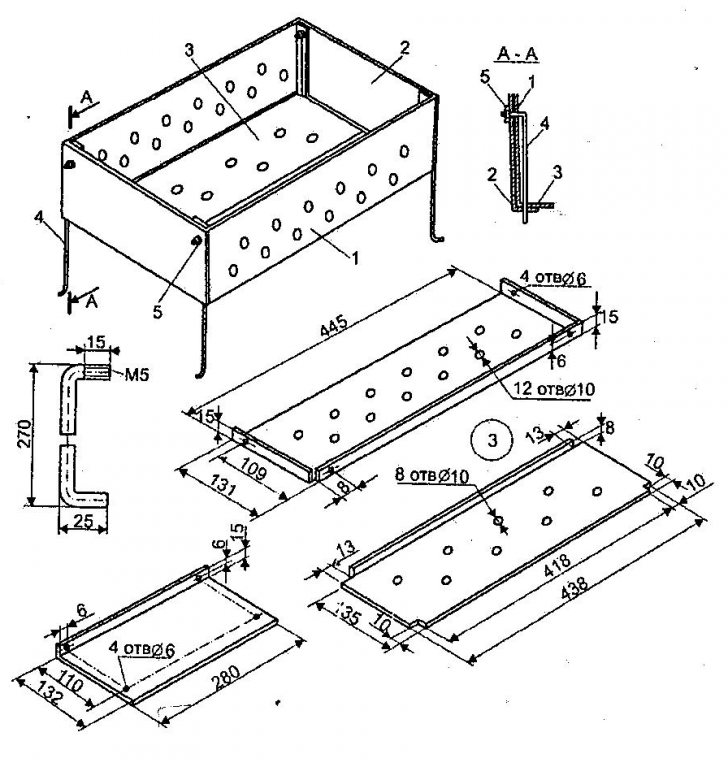

The next step is to create a working draft. It sounds loud in our case, but the presence of a metal barbecue drawing will speed up and facilitate the first assembly with your own hands.

We draw the project

The drawing will be absolutely successful and will be easier to read if you make it on a piece of paper lined with a cell. Be sure to note the height of the legs and the parameters of the frying box itself. Calculate the distance between the guide chamfers for laying the skewers and the perforations.

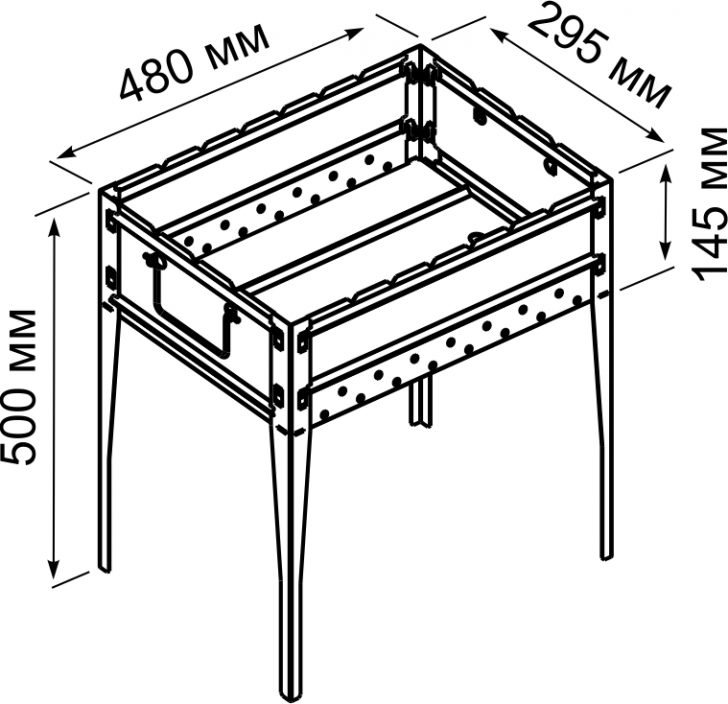

The average brazier is calculated on preparation of 8 portions of a shish kebab. The optimal distance between the ventilation holes is 7 - 10 centimeters. Position them correctly in the range of 5 to 10 centimeters from the bottom of the brazier. The length of the legs is arbitrary.

Metal barbecue project

Calculation of dimensions

An average company will be satisfied with a design for ten skewers. The kebab is good hot, so the next portion can be fried while the guests are busy eating the first one. For the meat to succeed, the skewers must be properly stacked over the coals. They can not be pressed against each other, but it is also wrong to push them too far apart. Heat should not be wasted. This is the main criteria for choosing the length of the frybox.

6 - 8 portion pieces of meat are strung on a skewer of standard length. If you do not want to reduce the portion, then make the width of the box according to the length of the first. There is no point in increasing the width. The product will become excessively bulky.

The depth of a do-it-yourself brazier made of metal should be close to the indicators proven by practice. Meat too close to the coals will dry out, too far away and not cooked. The optimal level of skewers above the fire is 30 - 35 cm.

Barbecue project for 11 skewers

The last parameter of the brazier is its overall height. He is taken out under the growth of the "chief chef". Invite him to your "construction site", give him a skewer and ask him to imitate the rotation of the latter, without bending over or bending his back. Measure the distance from the ground to your hand. You have obtained the optimal height of your product. If it is impossible to conduct an experiment, focus on standard indicators that vary from 80 to 120 cm.

Scheme of a brazier made of metal with a height of 50 cm.

Assembling the roaster

How good your brazier will be depends on the quality of the metal and the correct selection of dimensions. These two indicators will directly affect the cooking time of the barbecue and its taste.The work of a chef can go down the drain if the meat is cooked on poor equipment.

The portable brazier must be assembled from 2-3 mm metal, which is not as difficult to work with as with thick steel. It is not advisable to take sheets thinner, because a box of them will instantly burn out.

Portable brazier made of metal 2-3 mm thick.

The selected metal sheet must be "cut". Marking is carried out on a square. Its use is a guarantee of the absence of distortions. We have to draw 2 long and 2 end sides, as well as the bottom. To cut out the elements, we use a grinder. It is important to cut the parts so that their edges are even.

Cutting metal for barbecue

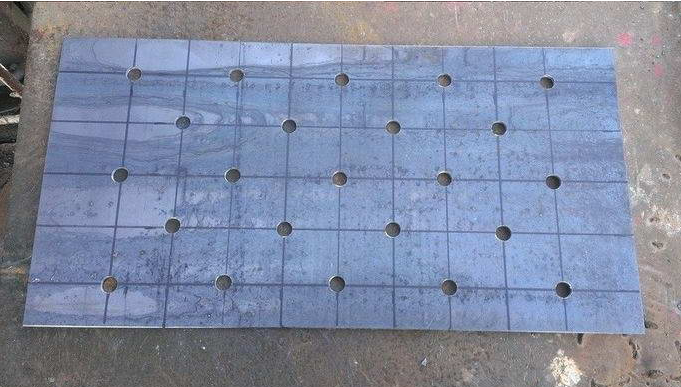

Now it's time to start perforating the walls of the brazier. The holes provide airflow into the brazier, which is necessary for good combustion of coals. We will drill them only along the back and front walls. Hole diameter 10-15 mm, step distance 5 cm.

Perforation on the wall of the brazier

The final stage of creating a brazier will be welding. It is better to perform them with a partner, since it can be difficult to keep the parts in the correct position and weld them with high quality.

Barbecue joint welding

"We put on our feet"

On the legs, you can use reinforcing bars, 30 mm tubes or a corner. The use of the first two materials will make it possible to make a do-it-yourself metal brazier collapsible or folding. For collapsible models, bolts are welded to the legs. You will have to work jewelry so as not to spoil the carving.

Reinforcing rods for barbecue legs

We make holes in the corners of the bottom of the brazier box. Their diameter should be slightly larger than the cross section of the bolts. Nuts are attached above the holes on the inside. After the metal has cooled down from welding, we try to put the structure “on its feet”.

The corners can be fixed to the base of the brazier permanently or make movable fasteners so that the legs, if necessary, can be folded. The first option uses welding, the second - bolting.

Bolted walls for a collapsible barbecue

If the legs are long, then they need to be strengthened by connecting them in pairs with jumpers. The latter can also be solid or folding (important for transforming models).

We collect non-standard do-it-yourself metal brazier

back to index ↑barrel model

If you move away from stereotypes and the fact that the brazier is a strictly rectangular structure, then you will understand that such a thing can be created from almost any suitable metal object, for example, a barrel that gathers dust in the corner of a barn.

Original brazier from a barrel

It is impossible to adapt only those containers where fuels and lubricants were stored under the barbecue. If the thickness of the metal of the looked after barrel is not too thin, then the structure will have a long life. The barrel will play the role of a brazier. In addition to it, you will need:

- drill;

- metal corner;

- welding machine;

- Bulgarian.

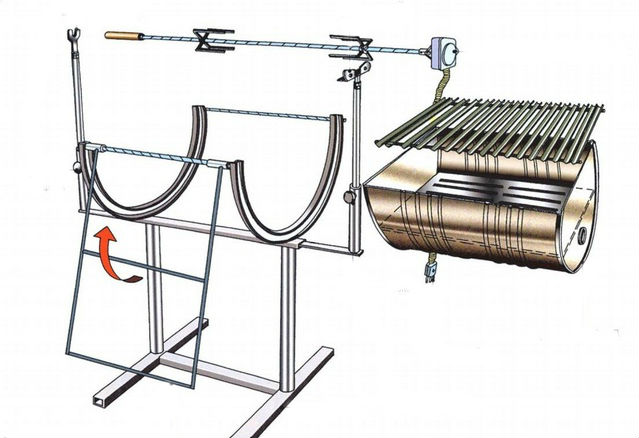

Barbecue project from a barrel

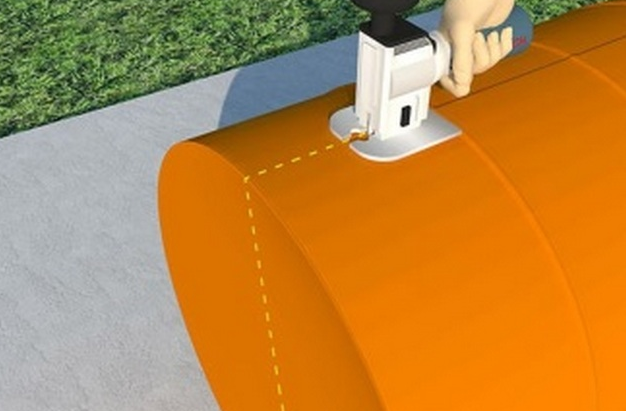

1. Having made the markup, we will cut out the upper part of the barrel, while maintaining the integrity of the ends. Do not rush to throw away the "production waste". A lid will be made from the piece removed.

Cutting the top of the barrel

2. The metal corner will act as legs supporting the structure. They need to be cut into 4 identical parts and weld the parts to the end of the brazier.

3. We measure the length of the barrel and prepare two more corners of the appropriate size. This will be the base for the skewers. At the corners, it will be necessary to make cuts with a step interval of 4-6 cm. We weld the prepared parts to the horizontal sections of the sidewalls of the barrel from the inside.

Brazier from a barrel on legs with a lid

4. Now let's improve a brazier made of such metal, and we will also do this with our own hands. Attach the lid to the base with hinges. Two handles should appear on its curved side. So it will be more comfortable to use.The lid will become both an element of decor and a functional part of the design, protecting the brazier and the barbecue that is being prepared on it from the rain.

The handle on the lid of the brazier from the barrel

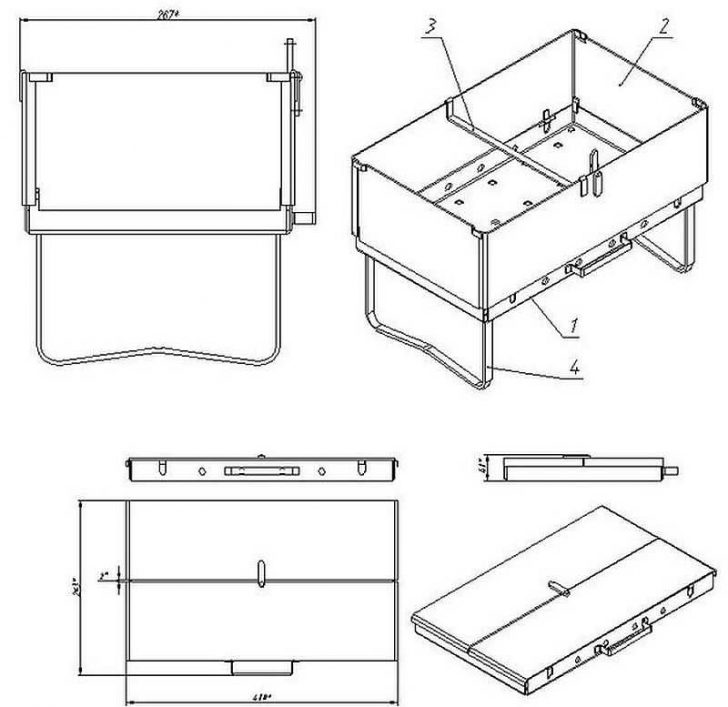

Collapsible model

The brazier can be made completely collapsible. In this case, the welding machine will not have to work. Here you need to act according to a different scheme.

Scheme of a collapsible brazier

The parts are cut with a seam allowance, that is, plus 3-4 cm on each side.

Next, you need to make bends on all sides of the resulting components in terms of the size of the allowances. This is necessary for corner docking and bottom fixing.

We will assemble the structure on bolts. We prepare holes for them with a drill.

folding model

Work on a folding metal barbecue will be carried out according to the standard scheme: drawing, cutting, assembly - only parts will need to be fixed to movable furniture body kits. To prevent arbitrary folding of the walls, special hooks are welded to their upper part.

Folding brazier drawing

Design of metal barbecues

"A win-win element of the decor of a metal barbecue, which you can add with your own hands, is forging"

The boring look of a home-made design does not threaten, because when working on a metal barbecue with your own hands, you are free to show your imagination and make it the way you see it, and not the way standards and concepts prescribe. Undoubtedly, it makes no sense to decorate the product with paints and varnishes. The heat will simply destroy all your efforts. But to play with the shape of the brazier, legs, add original details to the brazier - it’s very possible.

Original metal brazier

What and how to give the design of exclusivity? There are many ways. Make a lid for the brazier and complete it with an exhaust pipe. It will be interesting to watch. In addition, a brazier of such an assembly can be operated in a closed gazebo.

Brazier made of metal with a pipe

With the help of side stands, the brazier can be turned into a mini-plane. Also beautiful and practical. On improvised "wings" you can lay out ready-made shish kebab or string new portions of meat on skewers. It is not necessary to make the stands stationary. Removable elements would be nice too.

Do-it-yourself brazier plane made of metal

A win-win element of the decor of the metal barbecue, which you can add with your own hands, is forging. An ordinary piece of iron will become a work of design art. Maybe such an approach will not be fashionable, because today one-piece forged things are in favor, but beautiful, vintage, elegant will remain for centuries. Forging can be transformed, but it will never lose its aesthetic relevance.

Forged brazier does not lose its relevance

As a design option, the brazier can also be considered an “irregular” shape. Steel sheets can be bent, so it remains only to figure out how to bend them. Make the brazier oval, square, round, zigzag. Any option will be good.

Unusual oval brazier made of metal

Craftsmen can transform a perforated roaster into anything. Rummaging through childhood memories is not difficult to remember your favorite books or innermost desires. Dreamed of becoming a pirate and finding treasure? Make your dream come true now by creating a barbecue chest. Instead of legs, he may have crossed corsair swords. With the lid closed, the brazier can serve as a mini-smokehouse, just provide it with at least a small exhaust pipe for this.

Brazier - metal chest

Found in the attic space "grandmother's legacy" in the form of an ancient sewing machine, with a foot drive already forgotten by us? Do not rush to give it to scrap metal, because its bed is made of cast iron, which means it can become an excellent support platform for a do-it-yourself metal brazier.

Brazier based on a sewing machine

It does not give rest to inquisitive minds and the smoke coming from the barbecue.“Why not turn an ordinary barbecue into a steam locomotive?” - they think, and sit down for the project.

An unnecessary gas cylinder can become the main part of such a design. Having made the driver’s platform, welded wheels to the cylinder and installed a pipe on it, you will really surprise the household. It is desirable to make a pipe not fake, but real, so that it serves as a smoke exit channel. In the resulting hearth, it will be possible not only to fry a barbecue, but also simply bake or even smoke meat, as well as cook many more "dacha" delicacies.

Brazier with a cover from a gas cylinder

You will not believe it, but the front of an old car can also be adapted for frying barbecue. A car enthusiast who is friends with a grinder, welding and a head will do it in a couple of hours. A frying box with a grate is installed in the engine compartment empty from the insides, and that's it, you can start operating. Someone made such a brazier mobile, putting it on two wheels and providing it with a suspension and springs. It turned out to be a great trailer. Such a hand-made metal grill can be taken with you everywhere, like a field kitchen.

Brazier from the front of the car

Car wheels will also be used. They have all the prerequisites to become an excellent brazier without much effort on your part. They have a round shape, ventilation holes are already prepared, and the walls are thick enough that the fire will not burn through them soon. The only thing missing from the design is the bottom. It is also necessary to correct the native disc slots, which may turn out to be too big for small coals. For the convenience of laying out skewers, a steel holder can be integrated into the rim or simply used for cooking with a frying grate.

Brazier from car disks

Conclusion

As you can see, anyone can assemble a brazier from metal with their own hands, there is nothing complicated about it. Skills are a matter of life. And even if the first "pancake" may turn out to be lumpy, but later everything that comes out of your hands will cause real admiration, most importantly, do not lower them!

Photo gallery - do-it-yourself metal grill

Video