In the minimum program of the stronger sex, along with the need to plant a tree and raise a son, there is such an item as building a house. And at this stage, the regularity of its implementation is sharply inhibited: the lack of experience in the construction business makes itself felt. Questions arise sharply: what architectural option will he stop at and what is better to build a house from, so that it becomes a reliable shelter and a real family nest for more than one generation?

It is not so easy to get answers to them, because the modern market is rich in various offers. About the advantages of a particular construction technology and the quality of the materials used, experts themselves argue with foam at the mouth, which will not help you decide. You will have to try to understand the essence of the problem yourself. And it is worth starting the introductory tour with an acquaintance with the leading building materials.

Priority technologies of private housing construction

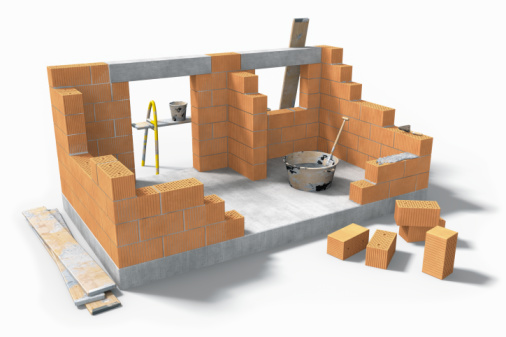

How and from what is it better to build a strong, habitable house today? You can work in two ways. The first one is called “wet” in the construction environment, because its technology provides for the use of a solution to fix the elements. These include:

1. Brickwork.

Building a brick house

2. Block monolithic construction.

Block monolithic construction

The second, respectively, is “dry”. Here the house is assembled, like a puzzle, from large parts. The latter are reminiscent of their design layer cake, where the "filling" is a heater.

Deciding on an impressive technology is not enough, you still need to find someone who masterfully owns it and whom you can trust categorically.

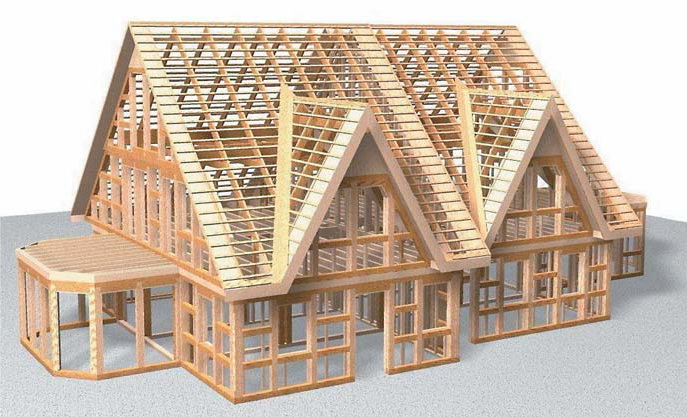

This is especially important for frame construction. Here and with what it is better to build a house from, you need not miscalculate, and hire builders so that they do not spoil the project. With the hiring of teams, in this case, you need to be especially careful. If you still need to be able to “screw up” a building made of heavy materials, then ruining the lungs is as easy as shelling pears. They need to be hung up on. Their layout and fit must be just perfect, therefore, the skill level of the workers must be above average.

Construction of a frame house

How to interpret "material is heavy" and "material is light"?

The question is natural, and the answer to it is already ready. "Heavy" materials are called because of their weight and overall dimensions. This category includes all representatives of stones:

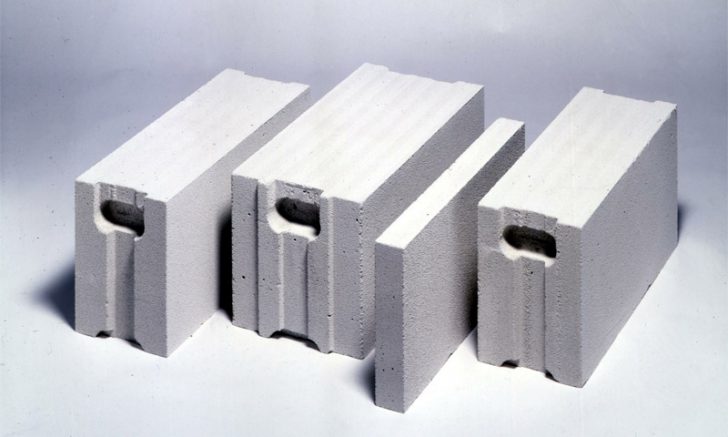

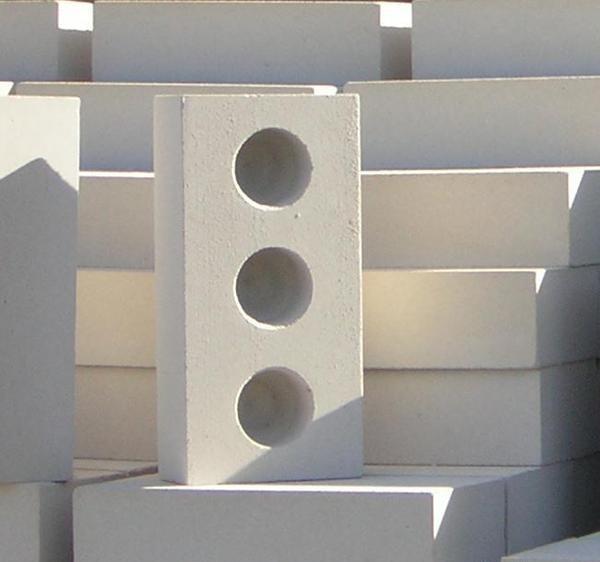

1. Aerated concrete blocks.

Aerated concrete blocks

2. Foam concrete blocks.

Foam concrete blocks

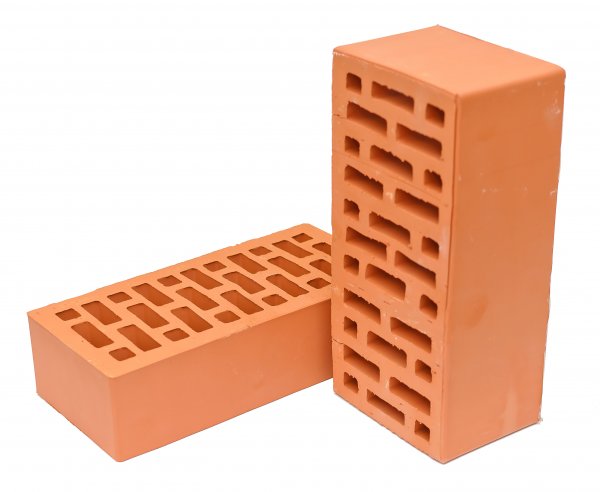

3. Ceramic blocks.

ceramic blocks

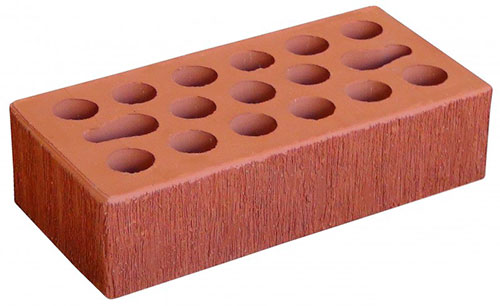

4. Brick.

Brick

Houses from the representatives of this group are placed on a powerful reinforced concrete foundation. Most often equip its tape version. Reinforced concrete slabs of increased strength are assembled on the floors, in which additional stiffeners are provided.

Strip foundation for houses made of “heavy” materials

The “light” include houses of panel-panel and frame assembly.The materials for the formation of their walls are really as light as possible, especially in the second option, therefore, they do not exert a strong load on the foundation, all the more so since wooden beams can be used as ceilings, rather than heavy slabs.

Assembly of a panel house

Here you can limit yourself to a columnar type of foundation or pour a slab. Such housing is being built very quickly, unlike monumental counterparts.

Column foundation for "light" houses

"Light" materials are also considered:

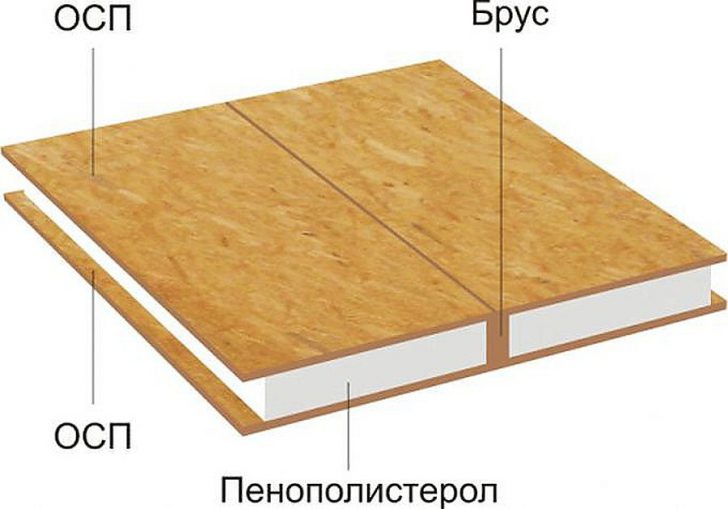

- SIP panels;

SIP panels

- wooden bar.

wooden beam

What is the best way to build a house: material characteristics

Brick

The service life of a brick house is at least 100 years. He will serve his due in any conditions, despite the zealous attempts of nature to put him out of action. The brick structure will perfectly survive both bitter frosts and withering heat. It will not collapse under the influence of hurricane winds and hail charges.

Reliable brick house

Since people started building brick houses a very long time ago, the technology for their construction has already been worked out even in small things, which means that there will be no problems with the masters.

Brick is divided into:

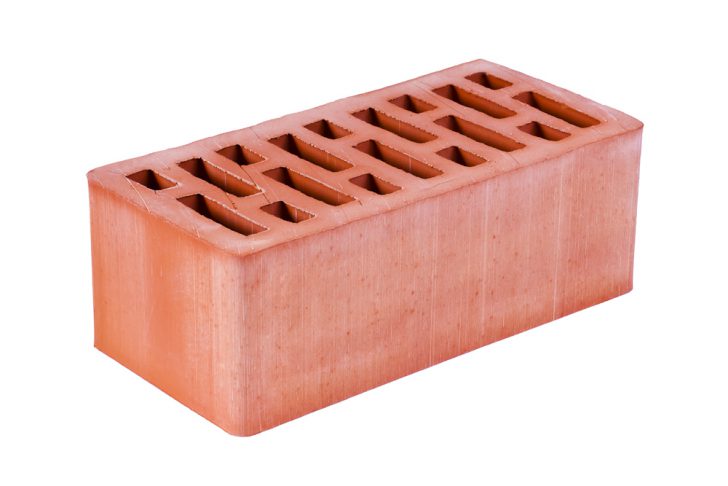

1. Ceramic.

ceramic brick

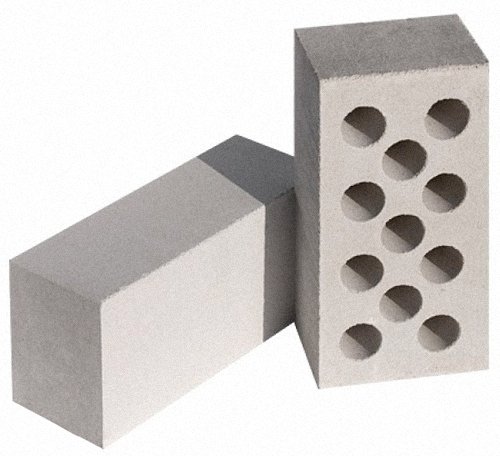

2. Silicate.

silicate brick

3. Private.

Ordinary brick

4. Facial.

face brick

ceramic brick

The material of this type is made of fired clay and has a red color. It is durable and highly environmentally friendly, non-hygroscopic and frost-resistant. Ceramic brick can be solid (voids occupy up to 13%) and hollow (voids account for 49%).

Hollow ceramic brick

The holes forming them can be located both horizontally and vertically. They are made in square, round and oval shapes. The more voids in the body of a brick, the higher its thermal insulation properties.

Ceramic bricks of various shapes

silicate brick

The main components of silicate brick are sand and lime, which makes it initially snow-white. It is also produced whole or lightweight. The latter is a good heat insulator, but the former is ready to please the developer with its color variety. Decidingwhat is the best way to build a house, no need to be wary of looking at lightweight product options. The presence of voids does not affect the strength characteristics of the brick at all.

Lightweight silicate brick

Appointment of an ordinary and front brick

Each of the presented types is designed for specific work. Private is used for internal masonry walls, which is why it is often called construction. The ideal appearance for the material in this category is not required. On the body of a brick there may be chips, cracks. Corners can also be notched.

Ordinary brick for interior masonry

But for the front brick, an impeccable appearance is simply necessary, so cracked specimens are ruthlessly discarded. This is done because this class of brick is used for laying out the outer surfaces of the walls.

Finishing the house with front brick

What does brick marking say?

The main indicator of marking is strength. It is she who determines the brand of brick. The indicator is indicated by the letter M. It is followed by a digital graduation. This is an indicator of the load maintained by one brick per square centimeter. The minimum strength of bricks produced today is 75, the maximum is 300. The higher the number on a piece, the heavier it will be.

Marking mark on brick

thought what is the best way to build a house? A little help. To drive out the walls of a two-story cottage, you need to purchase batches of bricks marked M125, at least M100. A stronger masonry will be required on the base, so it is right to work here with the M150 brand, and maybe even M175.The choice will depend on the expected weight load from the upstream structural elements of the house, such as: roof frame, type of floors, etc.

Brick M 125 for the construction of a two-story house

Having decided to dwell on such a building material as a brick, it is necessary to take into account its frost resistance indicators. For our climate, this is more than relevant. It is necessary to find a class of brick that will calmly respond to critical temperature changes.

Frost-resistant brick F25

The degree of frost resistance is indicated by the presence of the letter F in the marking and numbers from the digital corridor 15-100. The latter indicate the number of freeze / thaw cycles that the material will endure without damage. For warm regions, you can safely purchase the F-15 category for external walls, in a temperate climate the F25 brand is well used, but F50 brick should be used for facing. Looking at the above examples, you can already independently determine, what is the best way to build a house in your area.

Frost-resistant brick F50 for cladding

Summarize

Material advantages:

1. Aesthetic look.

2. The ability to implement a project of any architectural complexity.

3. Durability.

4. Immunity to moisture.

5. Fire resistance.

6. Good sound insulator.

Flaws:

1. Massiveness.

2. The complexity of the masonry.

3. The need to involve specialists.

4. Mandatory arrangement of the foundation of increased strength.

5. Weak heat insulator.

Attempts to add energy-saving qualities to bricks have been going on for decades, but so far they have not been particularly successful. Together with the laboriousness of the process of laying walls, due to the small size of piece products, this suggests looking for an alternative replacement for the material.

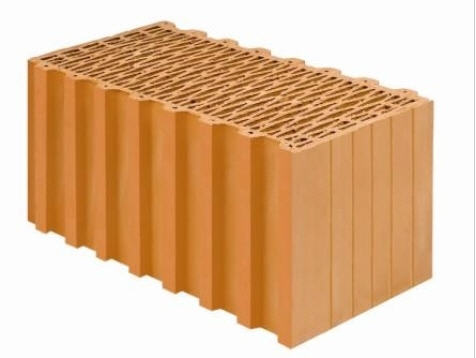

Keramoblock

This representative of modern building materials is very popular in Europe. It is chosen for its environmental friendliness, speed and low cost of installation. From the ceramic block, you can build multi-storey buildings. The margin of safety of the material is sufficient for this. The operational life of such houses starts from a century and a half mark. Keramoblocks have a porous texture and a beautiful corrugated surface. The elements are mounted using a tongue/groove connection.

House made of ceramic blocks

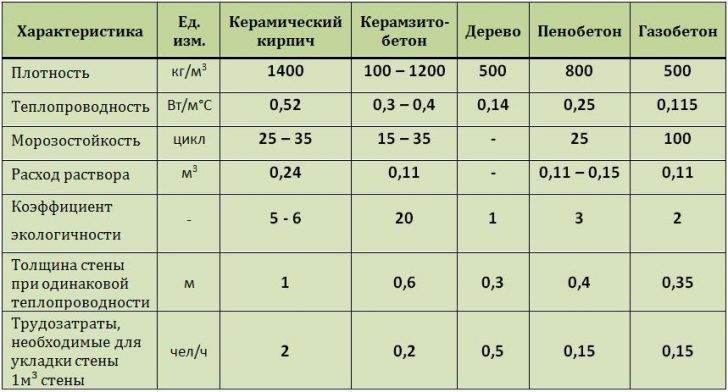

Material characteristics

Looking for an answer to a question what is the best way to build a house, take a closer look at the ceramic block. With different lengths and widths, the height of any block remains similar to brick, which allows them to be used in the implementation of projects designed for brick houses.

Comparative characteristics of ceramic blocks

The length of the block determines the thickness of the future walls and varies between 25-51cm. The width is 23-25 cm. It is noteworthy that the maximum dimensions of the kearmoblock have a weight of only 25 kg, and in terms of masonry volume it corresponds to 15 bricks, each of which weighs 3.3 kg.

The benefit is obvious:

- low load on the foundation;

- fast assembly.

For laying the load-bearing parts of the structure, blocks with a length of 30 cm or more are needed. In order not to bother with additional insulation, it is rational to drive walls with a thickness of 38 cm or more. In terms of frost resistance, the material is also resistant, like a brick, and is designed for 50 cycles, regardless of other strength indicators.

Keramoblock 30 cm for load-bearing parts of the house

Perhaps, after looking at the list of advantages of the ceramic block, you will understand what to look for, what is the best way to build a house, no further. Indeed, the material has much more pluses than minuses. What attracts?

– Low weight with high strength.

– Possibility of use in multi-storey projects.

– Quick and easy installation.

– Economical use of the solution. It is needed only for fixing horizontal seams.

– High level of frost resistance.

– Fire resistance for 4 hours.

- Excellent soundproofing qualities.

– Low thermal conductivity.

Disturbing:

– High material cost.

– Complicated search for real specialists in working with ceramic blocks.

– Increased fragility, requiring careful transportation and proper storage.

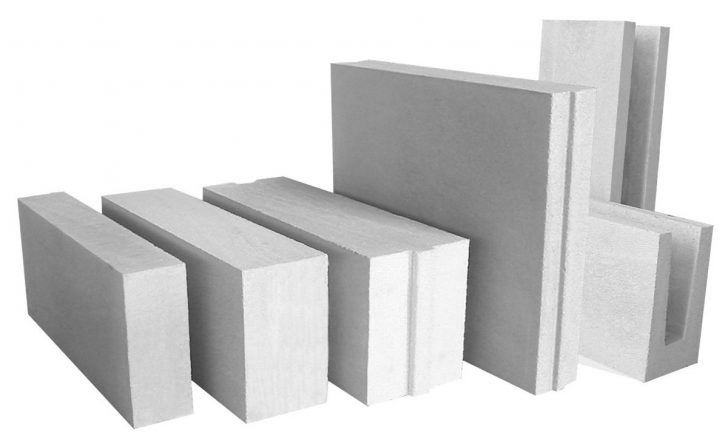

Aerated concrete blocks

Looking for what is the best way to build a house, you may stumble upon ads for gas blocks. Their appearance is less aesthetic than that of the previous material, but this is offset by the ability to retain heat well.

Aerated concrete blocks retain heat well

A single-layer wall made of gas-block in its characteristics is in no way inferior to multi-layer brickwork. Since the material perfectly resists moisture and temperature fluctuations, a pleasant microclimate is formed inside the house. Aerated concrete is not limited in terms of operation. It will not rot or break down over time. High thermal insulation qualities are provided by the internal porosity of the blocks.

Main characteristics

Working with aerated concrete is a pleasure. The consumption of mortar for masonry is minimal, and due to the large size of the blocks, it goes very quickly. The material is easily cut with a hacksaw, so there will be no problems with removing architectural forms. Thermal insulation performance can be improved by thin-seam assembly technology, in which an adhesive composition is used instead of a solution. Factory production of gas blocks provides them with ideal evenness of cuts, which is well reflected in the quality of the resulting wall surface and should be taken into account when making a decision, what is the best way to build a house. For interior finishing, the leveling step can be skipped.

Masonry of aerated concrete blocks does not need additional alignment

Pleased with the low cost of transportation. Light weight allows you to load the material in large volumes and it also makes it possible to switch to work with it at any construction stage.

Aerated concrete is not combustible, has an excellent indicator of strength and environmental friendliness. The level of its vapor permeability is similar to wood. Its frost resistance indicators are also good.

The main parameter for choosing a gas block is its density (D). Its indicator varies between 350 - 1200 kg per cubic meter.

Density of aerated concrete blocks

From what, taking into account everything written, it is better to build a gas-block house? Made of material grade D500 or D900. The standard block has a weight of 18 kg and replaces 20 brick units in volume. A very serious argument in favor of this type of material.

Wall aerated concrete block D500

Results

- You can drive a house out of gas blocks 9 times faster than building a brick one.

- You can build with your own hands.

– The accuracy of the geometric dimensions eliminates the unevenness of the finished surface.

– High compressive strength and minimal thermal conductivity.

- 100% fire resistance and no toxic emissions when heated.

- Porosity allows the walls to ventilate and not suffer from temperature changes.

Aerated concrete blocks have 100% fire resistance

Of the shortcomings noted:

– Low bending resistance.

– Possibility of cracking blocks over the years of operation.

– The need for careful storage, preferably in warehouse conditions. At the construction site, blocks require protection from the weather.

- A gas-block house needs a solid foundation.

Tree

When solving a problem, what is the best way to build a house, probably the first material that came to your mind will be wood. And this is not at all unfounded. A wooden house is always cozy and has a unique healthy microclimate.

Traditional wooden house

But let's not rush to conclusions and thoughtlessly believe the advertising of round logs, as well as profiled timber with other options, but let's try to soberly assess their advantages and get acquainted with the disadvantages.

Log cabin in manual execution

The oldest method of construction, which came to us from great-grandfathers. In it, tree trunks are cut to the required length and completed with locks and grooves.This is followed by the assembly phase of the structure. The delivered house is left to sit down. This process will take about a year. The final stage will be the sheathing of window openings, door frames and sealing cracks.

Handmade wooden house

Today, individual craftsmen work in this way, which is not easy to find, and is it worth it if it is possible to build using other methods?

bar

This term refers to factory-processed logs. Each unit that comes out from under the machine is subject to mandatory marking. Parts ready for assembly are brought to the construction site.

Assembling a house from a bar

The beam differs in the shape of the section, so you can choose What would you like to build a house from?. It can be seen:

- square;

- rectangular;

- semi-oval.

Semi-oval timber

The profiled model will have connecting tabs and slots added. The presence of an oblique cut will contribute to better drainage of water. Ease of assembly is conducive to working on the house with your own hands.

There are several categories of building timber.

Sawn timber made from high-moisture logs (as a percentage, the degree of moisture reaches 50-70%). Such houses give a strong shrinkage, because of which they can become covered with cracks.

Sawn timber

Planed timber goes through the drying process. At the outlet, the moisture content of the material does not exceed 25%. Products must be sharpened. The result of this treatment is minimal shrinkage.

Planed timber

Glued laminated timber - a prefabricated product, but it is he who should be of most interest to those who are looking for, what is the best way to build a house. The material consists of several layers of glued lamellas. Humidity in such boards is 6-10%. Gluing takes place under pressure, and the wood fibers in each subsequent layer are perpendicular to the direction of the previous ones. This type of timber is not subject to shrinkage processes, deformation and cracking.

Glued laminated timber

What we have:

- The greatest environmental friendliness.

- Putting up a house from a bar is much cheaper than a brick one.

– Minimum thermal conductivity. It is always warm in wooden houses.

- Primordial beauty. There is no need for decorative finishing of either the facade or the interior.

– Can be placed on a light foundation.

- A wooden house (especially hand-made log cabins) has been serving for centuries.

A wooden house can be built on a light foundation

Flaws

There are few of them, but they are quite serious:

– Wood burns well, is prone to rotting and is loved by fungi. You will have to regularly treat it with the appropriate compounds.

– Protracted shrinkage process. Sometimes it stretches up to 5 years.

Frame house

Need a home urgently? Frame technologies will come to the rescue. How about what is better and faster to build a frame house?

Prefabricated frame house

The most difficult thing in such a house is to assemble its foundation. For the manufacture of the bearing part, both wood and metal are taken. Further - everything is fast and simple. The walls are obtained by sheathing the frame structure with dense chipboards or OSB, between which an insulating layer of insulating material is laid. The weight of the finished wall is minimal, which eliminates the need for an expensive foundation.

Frame house model

Insulation becomes the main item of expenditure in a house of this type. However, even in the case of purchasing the most expensive version of it, the total estimated cost of the building will turn out to be one and a half times cheaper than a wooden one and almost three times cheaper than a brick one. A good reason to think what is the best way to build a house?

Frame houses are built of two types. In the first case, they are assembled from shields. Of these, they first drive a common box of the building, and interior partitions put later. The finishing touch is the roof.

Assembly of a panel frame house

In the second version, the “frame” becomes the basis of the house. This frame is assembled from logs and beams and rests on a foundation base.After that, the rafters are installed, and the crate is made. Having erected a roof, they proceed to stuffing the walls with insulation. The final step is the outer casing.

Construction of a frame house

Positive side of the issue:

- An extremely successful duet of the price of the issue and the speed of installation.

- Outstanding performance in energy saving. Left without heating in a ten-degree frost, a frame house will cool down by only 2 per day.OWITH!

– No need for interior decoration.

– Trouble-free solution to issues of redevelopment and design improvement.

– Hidden communications.

Negative characteristics

- The strength of the walls is low. They are easily destroyed by mechanical action.

- The frame structure is less tenacious.

- You will have to work on standard projects. It is unrealistic to deploy a fantastic construction site with such technologies.

- The need for ventilation.

Standing at a crossroads and choosing what is the best way to build a house, adequately assess your capabilities and adjust your desires to them.

SIP panels

There was a lot of controversy about the environmental friendliness of this material. Panel manufacturers emphasize the progressiveness of "Canadian technology", which, in fact, can be interpreted as a simple marketing ploy.

The design of the panels is not burdened with frills. Here, they simply laid a layer of non-burning heat insulator - expanded polystyrene - between the OSB boards. The panel is a finished part of the wall, so it remains just to dock the elements together.

SIP panel house

It should be noted that the material is suitable not only for the construction of walls, but also for arranging the base of the floor, ceilings, and roofs. Although the house is light, it turns out to be very warm. The price segment of houses from SIP panels is average.

A house from SIP panels can be built within a month

If you think that such panels are exactly what you need, what is better to build a capital house, then you should remember to equip it with a powerful ventilation system to get rid of the effect of a thermos. As for the pace of construction, the housewarming can be done within a month.

cinder block

80s stuff. In those years, it served as an inexpensive alternative to the incredibly scarce brick. In modern construction, they are almost forgotten. The large weight of the cinder block, combined with high thermal conductivity and the need to insulate the walls from it with ecowool slabs or a mannered analogue, with a layer of 15 centimeters, does not give rise to a special desire to start with such construction.

cinder block house

Add to this the need for a decorative facade finish, which will further increase the cost of the project, and the conclusion suggests itself: cinder block is not the material from which it is better to build a modern house.

back to index ↑A short tour of private housing construction

Material and workers are just a part of the iceberg of questions that will pile up on you when building your house. Let's look for answers to the leading ones.

Which house will be more comfortable?

“Attention will require not so much the question of what is better to build a house as the task of arranging good ventilation in it”

We must pay tribute to modern construction methods, because no matter which house you choose - “light” or “heavy”, living in both will be comfortable. They form a wonderfully balanced microclimate with suitable temperature and humidity, and it is maintained at this level all year round, without reacting to weather changes. Of course, all this is true only for those buildings that were built from environmentally friendly materials and without disrupting technological processes.

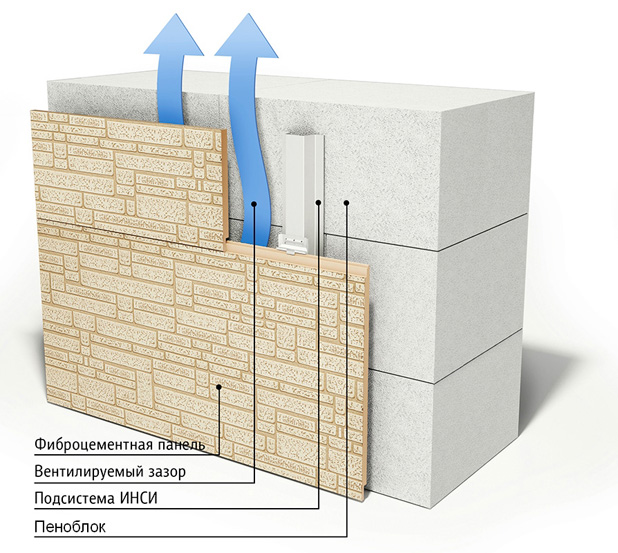

Attention will be required not so much by the question of what is better to build a house from, but by the task of arranging good ventilation in it. The last problem is most relevant for heavy structures. It is very important here that the wall surfaces do not suffer from moisture.Not only will they become just a plantation for the growth of the fungus, they will also stop keeping warm. A vapor-permeable finish of good quality will be a good obstacle to moisture.

Vapor-permeable home decoration

A few words should be said about "light" houses. For everything to be fine, do not sheathe them from the inside of the chipboard. The composition of the plates contains unsafe phenol. An alternative solution would be drywall.

Sheathing the house with drywall

Comparative analysis of residential structures

What do you think it would be better to build a house from, so that it will turn out to be of unprecedented quality? Do not soar in the clouds! The ideal house does not exist, each design has its own disadvantages and advantages.

frame houses

Pros:

- They are inexpensive.

- Build quickly.

– There is no need to deploy a large-scale construction site on the site with the allocation of additional space for storing materials and carrying out auxiliary work.

Frame houses are being built quickly

Minuses:

- Less durable than "heavy" counterparts.

- You can not invest in parts.

- Fire safety will require a location at a maximum distance from other buildings.

- Weak resistance of the walls to mechanical stress.

capital houses

Pros:

- Home forever. Estimated operating time of 100 years.

– Opportunity to invest in construction in separate parts of the amounts.

– High structural strength.

- Fire safety.

– Departure from standard construction. You can design houses in any architectural form.

Capital houses are highly durable

Minuses:

- Long-term construction. It will not be possible to enter the house not only in a month, but also in a year.

- The need to deploy a serious construction site.

Looking at this summary, it will be easier for you to understand the ultimate goal of the event and decide what is best to build a suitable house from.

Financial niceties

“You can adjust the estimated cost, independently deciding what is better to build a house from: OSB or less expensive SIP panels”

The price of the question is a rhetorical aspect. In housing construction, everything is directly proportional. A house that should stand for centuries cannot be built for five kopecks, so all monumental buildings will be from a series of expensive ones. Now you can also find projects of frame options designed for prolonged operation, however, in terms of their cost, they are not far behind their brick counterparts.

Modern frame houses are designed for prolonged operation

"Light" houses in the standard version are more acceptable financially. Here you can adjust the estimated cost, independently deciding what is better to build a house from: OSB or less expensive SIP panels. Add to this a lightweight foundation, minimized transportation costs, and a low labor intensity of the process, and you will see that the total cost per square meter of construction will be $ 200 cheaper than in the case of a “heavy” house.

A house made of SIP panels is financially the most profitable

In the segment of stone buildings, the most budgetary option will be built from cellular concrete, and the most expensive one will be brick.

Conclusion. If you do not have a dimensionless budget for building a house and are not ready to get into debt, then your ideal option is frame housing. It will be possible to compensate for the impossibility of exclusive design with an interesting finish and an increase in living space.

When is installment payment allowed?

Sometimes there is a situation when initially there is not all the amount required for the construction on hand. There is no catastrophe in this, because in some cases it is quite acceptable to invest finances in stages. It should be borne in mind that by delaying investments, you increase the final amount, so if you can make an advance payment in full, use it. Let's figure out what is better to build a house in a situation of financial shortage?

Gradual investment of funds is justified in capital construction.Here you can, by kicking the box, suspend it for the right time. Resuming work at the facility, upon the appearance of the next batch of money, will not be difficult. It is impossible to do this with frame houses. Here you can only postpone the interior decoration, taking up it when the required amount has accumulated.

Which project to take?

It all depends on the goal. If you want the best housing option for a limited amount, then it makes no sense to take a layout with the possibility of subsequent extensions and additions, so that in subsequent years you do not jump out of the skin, scraping up finances for an exhausting series of housing conversion works. Approach the task from the same side with which you decided the question of what is better to build a house from. Believe me, in order to make living in personal apartments a pleasure, it is much more rational to build them in a more modest, but most effective form from a practical point of view.

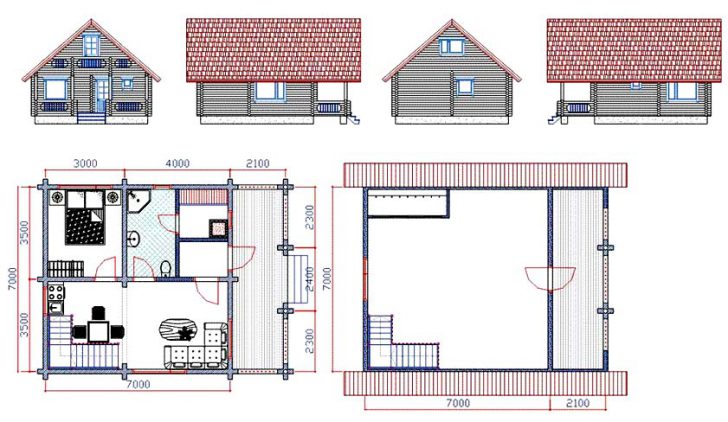

When building low-rise housing, look at projects with attics. This is no longer a cramped one-story building, but also not a full-fledged two-story house. In such a house there will be where to turn around.

Project of a house with an attic

A light house needs to be built according to a finished project. You can find an interesting option in specialized companies. There you will also receive a complete set of assembly elements. With regard to finishing, you will have complete freedom of action.

light house project

This does not mean that when choosing this type of building, you will be dictated from what and in what style it is better to build a house, and you will not be able to order the development of an individual project for a light structure. But keep in mind that even in this case there will be no deviations for the sake of architectural delights from the general requirements for frame construction, so is it worth overpaying for an exclusive floor?

Typical project of a frame house

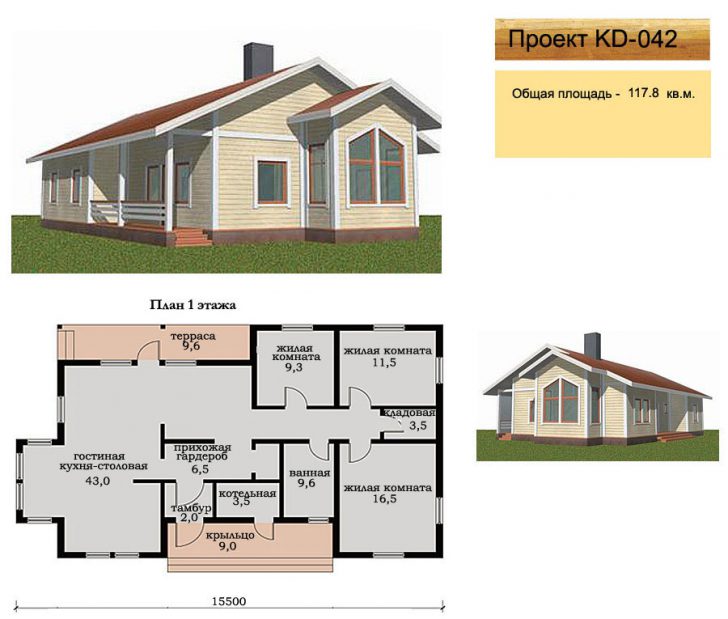

The capital house in terms of design has no restrictions. Here it makes sense to ask to develop an individual version of the building, because you can be sure that your wishes will not only be heard, but also guaranteed to be implemented.

Ready-made proposals have other advantages. Looking at them, you can immediately look inside the buildings, that is, visually assess the harmony of the layout and even estimate the interior design.

Typical project of a capital house

And yet, the main criterion for choosing a construction project will remain the cost of 1 m2, because it is necessary to fit into the budget.

How long will construction take?

It is possible to talk about the timing of housewarming only after the choice of technology. If you have already chosen what is better to build a house for yourself, then you can figure out how long it will take. What should be said right away is that heavy walls cannot be quickly driven out. Construction will not go on for at least a year, and this is if the house is planned to be small, 150 square meters. Only it will take about a month to fill the foundation here. For a couple of months, the builders are busy with laying the walls, then the laying of floors, installation of the roof, insulation, insertion of window frames, installation of engineering systems will begin, and this is almost 4 more months. Finishing work will not pass quickly either, because for them to start you need to wait for the final shrinkage of the house, so no matter how you twist it, you can’t manage it in a year.

Capital house with an area of 150 sq.m.

The absence of "wet" masonry processes significantly speeds up the construction process. The frame house can be occupied in a maximum of 2 months from the laying of the foundation. If all the necessary materials are purchased and delivered, then the construction will be carried out by leaps and bounds. A lightweight foundation will take two to three weeks. There will be a slight delay during the construction of the frame, and then everything will roll at an increasing speed. How long the walls will be sheathed with insulation or building panels will depend solely on the dimensions of the building.This will be followed by finishing work, which in the case of a frame assembly of a house can begin immediately, since there is no shrinkage process here.

The frame house is being built within 2 months

If the criterion for choosing what is better to build a house from is speed, then light structures are more relevant in this regard.

Which house will be the fortress?

If you want to get a house so that it cannot be penetrated, as they say, “through the walls” - stop at heavy materials. A stone wall cannot be broken through either with bare hands or with a tool, except that a tank can drive in from acceleration. But even in this case, the gap can be easily closed by laying the opening with a brick or other stone. In this case, you do not have to worry about irreparable or dangerous structural damage.

Sturdy brick house

The situation with frame houses is quite different. Here the strength is due to the quality of the skin. By and large, you can cut any of them with a grinder. But under it there will be a heater, then also a barrier layer of drywall. There will be a catastrophe if the frame is hooked, although even in this case it will be possible to try to limit oneself to local restoration and not resort to radical measures.

What to build on a small lot?

If the site has already been inhabited, a garden has been grown, there is a utility block, then undoubtedly it is necessary to choose a light structure. Heavy houses will require scope. On an already modest territory, you will have to look for a place not for one foundation, but also for mixing concrete, storing materials, carpentry and heaps of garbage, so it is better to leave stone buildings for empty, not yet cultivated, allotments.

back to index ↑Conclusion

When choosing what is better to build a house from, you will have to look at many factors, so I want to make your task easier once again. Analyze how each option offered to you fits into the universal formula “cost-energy-saving-environmental friendliness”, and if the ratio of indicators suits you, then you can look at the material and the technique of working with it in more detail. Good luck!

Video