Wood, as a building material, will never leave our everyday life, the atmosphere in such houses is too good and cozy. No less magnificent is the exterior of the logged building.

Today it is not difficult to give it both a modern and fabulous look. There are many different technologies for this. But how to sheathe the walls in a wooden house? Their unusual structure probably requires a special approach, because just sticking wallpaper will not work here? Indeed, without preliminary preparation it will not work, and it is worth talking about this in more detail.

Criterias of choice

The choice of finishing material for interior work in a wooden house will depend on the region in which the object is located and how it is planned to be used. If it is planned to spend only summer outside the city, then it is quite possible that you would prefer to simply paint, treat with a tinting solution or varnish the wall surfaces, without particularly bothering with their alignment and other finishing work.

The walls of a wooden house, varnished

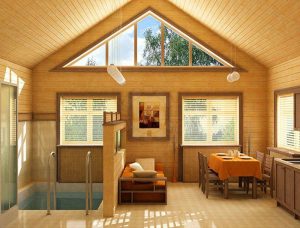

For year-round living, such solutions may not be entirely adequate. The need to create an interior style, where the appearance of the walls plays an important role, cannot be discounted. In many cases, their surface must be perfectly flat, which is achieved by decorative trim.

back to index ↑Types of finishing materials

“Ash has proven itself well, which is practically not afraid of high humidity, so products from it can be used in rooms of any functionality, without restrictions, but coniferous lamellas will emit resin when heated, which means that in the kitchen such material is in the finish better not to use"

How can you sheathe the walls in a wooden house today? Designers actively use:

1. Wooden lining.

2. Various panels.

3. Block house.

4. Drywall.

5. Decorative stone.

6. Plastic.

If you decide on wood derivatives, then be sure to consider the qualities of the wood from which they are made. Ash has proven itself well, which is practically not afraid of high humidity, so that products from it can be used in rooms of any functionality, without restrictions, but coniferous lamellas will emit resin when heated, which means that in the kitchen such material in decoration is better do not apply.

Sheathing of walls in a wooden house with ash

Often the walls carry the weight load. Furnishings and decor are attached to them. This should also be taken into account when choosing a material, as it must have an appropriate margin of safety for the implementation of such design delights. You can find out how suitable this or that material is for interior decoration by getting acquainted with its characteristics.

Wooden lining

Wood is an easily processed material. It is easy to cut, plan, grind. The material has a wide palette of shades and a variety of textural patterns.Wood is an excellent sound absorber and heat insulator. Proper fastening of the skin will allow it to operate for many years.

Wall cladding in a wooden house with eurolining

The energy of the tree is also pleasant. In a room with such decor there is no place for depression and despondency. The atmosphere in it always stimulates an increase in mood.

At its core, the lining is an ordinary board with special fastening grooves, which makes it possible to tightly fit the elements to each other when sheathing the wall.

The lining has excellent thermal insulation properties

Browse the product range, look for models designed for indoor use. They will also be presented in different profiles and sizes. Their surface can be either raw or perfectly smooth, which also facilitates the task of the designer when working on creating an interior style.

Types of lining for wall cladding

When getting acquainted with the characteristics, pay attention to the type of wood used to make the lining you like. This item is required if you are choosing a sheathing not for well-ventilated and dry rooms. For the bathroom, it is better to choose not coniferous derivatives, but options from linden, oak, alder.

Coniferous wood paneling for bathroom

Wooden lining is extremely popular. It can be found in almost every home, and this pattern of finishing material often stops admirers of individuality. But still, this fact does not detract from the merits of lining, because it:

- practical;

- universal;

- environmentally friendly;

- presented in a large species and quality assortment;

- exudes a wonderful aroma.

Lining for wall cladding is versatile and environmentally friendly

The cladding is mounted on a frame structure assembled from metal profiles or wooden bars. This is the easiest way to hide the unevenness of the bearing surface. The slats are fastened to the crate with clamps or, in the old fashioned way, with screws and nails.

Wall cladding in a wooden house with clapboard

When choosing a mounting method, consider this nuance. If you purchased a lining that has not undergone chamber drying, then the lamellas will gradually lose moisture, that is, dry out, which means that gaps will certainly appear between them. There is no way to avoid the process, so you will have to:

1. Accept what is happening.

2. Correct the situation.

Sometimes you have to adjust the lining several times, so before you nail the lining tightly, think about how you will remove it if necessary. Self-tapping screws can be the best solution in this case. It will be easy to unscrew them during reconstruction.

Fastening the lining with self-tapping screws will allow you to further disassemble the skin

You can purchase profiles, during the assembly of which, the cracks from drying out remain almost invisible. It can be "Softline" or "Standard".

Eurolining

Outwardly, this sheathing material is associated with ordinary lining, but its characteristics are many times superior to it. In the first place comes such a weighty argument as German quality. Eurolining slats are well ventilated and have an additional furrow that functions as a moisture removal system. This increases not only the service life of the skin itself, but also the wooden wall hiding under it. The euro analogue will not have problems with surface deformation associated with swelling, which makes it the No. 1 material for finishing bathrooms.

Wall cladding with eurolining is absolutely not subject to deformation

The surface of the lamellae is perfectly smooth and tactilely pleasant. Products are initially treated with protective compounds, which eliminates the need to do this before assembly, as when working with ordinary class lining. The beauty of the wood structure and the uniqueness of its pattern do not suffer from such procedures.

Plasterboard sheathing

Finishing the walls with plasterboard will help to hide construction defects and hide communications.Behind its sheets there is a place for a heater, and they themselves are good heat and sound insulators. The material is able to regulate the microclimate of rooms by absorbing and releasing moisture.

Drywall sheathing maintains the microclimate in the room

Its structural qualities are incredibly attractive. The drywall sheet can be bent, which allows you to give the walls and corner joints an arbitrary shape. If you decide to sheathe the walls in a wooden house with drywall, then at the same time protect them from damage by rodents. The secret is that during production, the sheets are impregnated with some chemical compounds, which repels living creatures.

Plasterboard sheathing will protect the house from rodents

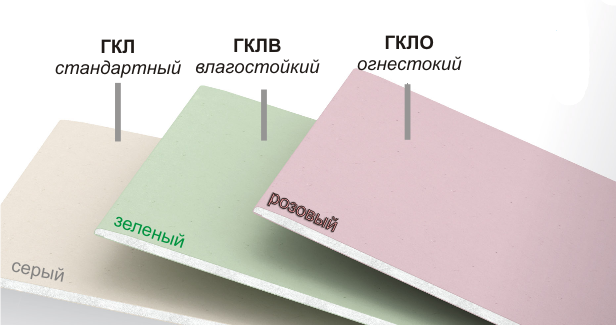

The material is presented in a varietal variety.

In rooms with normal humidity, wall drywall is used. In damp rooms, a moisture-resistant type is used, and in places with high temperatures and a risk of fire, drywall with a fireproof coating is used.

Types of drywall for wall cladding

Any of the presented species is environmentally friendly and has an affordable price. The large size of the sheets guarantees the speed of installation of the skin. The resulting surface can be painted or used as a base for laying tiles and applying decorative plaster.

Drywall can be painted in any desired color

The technology for installing plasterboard cladding in a country house made of wood is no different from the process of finishing the walls of city apartments. The frame is assembled in the same way and sheathing sheets are attached to it in the same way.

Since gypsum is a fragile material, it can only be used in the design of houses where the shrinkage process has already been completed. Be sure to leave a gap of a few centimeters under the ceiling and near the floor. The wooden walls of the house remain "alive" always. They swell in wet weather and shrink in the heat. Wrongly made skin will simply tear. You can ignore these processes of life at home by installing a floating frame, which is ensured by non-rigid fastening of profiles to the wall. Having a margin of movement, the profiles will be able to keep the drywall in its original position, no matter how the log house behaves.

The process of sheathing the walls of a wooden house with drywall

It is possible to protect the surface of the skin from the formation of cracks by reinforcing all joints and corners with a reinforcing mesh made of polymers.

It is permissible to sheathe the walls of a wooden house with drywall without assembling the frame. In this case, I will mount them on rails, bars and adhesives. Thus, additional area is won, which is very important for small rooms.

Wall panels in the interior decoration of wooden houses

Decorating the walls inside a country house with special panels allows you to diversify the stylistic solutions of interior decor. This is guaranteed by the textured variety of the material.

Wall panels produce:

- from fiberboard;

- MDF;

- bamboo;

- plastic;

- glass;

- skin.

The most popular are fiberboard panels. They came to interior design not so long ago. The material is classified according to species diversity.

Finishing the walls of the house with fiberboard panels

Type-setting rack models have a small width (10-30 cm), various lengths (from 2.5 m to 6 m) and thickness (8-2.5 mm), which are very reminiscent of wooden lining. The association is strengthened by the presence of a similar tongue/groove connection scheme and the method of attaching the sheathing to the walls of a wooden house, where brackets and clamps are used.

Rack fiberboard panels

Tiled types are also presented in a variety of sizes and colors, which allows you to hide walls behind real panels or reproduce the most incredible patterns in the sheathing by combining tile panels of different shades and shapes.

Finishing with tiled fiberboard panels

Sheet options are offered in an equally wide range of sizes and are very similar in appearance to hardboard sheets. Their surface can simply have a solid color, and be decorated using the 3d technique.

MDF sheet panels for walls

The laminated coating of fiberboard panels imitates both the structure of natural materials such as marble, granite, wood, tiles, metal, and pleases with fantasy motifs. Elements can be covered with bright patterns, ennobled with mirror inserts, picture reproductions, stucco or thematic plots.

Laminated fiberboard panels imitate natural wood

Fiberboard panels are durable. Self-tapping screws are securely fixed in them, so there will be no problems with fastening the shelves of lamps and other accessories. For all types of fiberboard wall panels, you can choose suitable fittings and moldings to decorate joints and hide wall defects.

These include:

1. Moldings.

2. Corners.

3. Skirting boards.

4. Plinth strips.

5. Platbands, etc.

With the help of such elements, a single interior style is formed, so do not refuse to use them.

MDF panels, due to their water resistance, are most often used in bathroom decoration. The option is cheap, convenient and environmentally friendly. Panels of this type are easy to install, have good thermal insulation performance, are durable, wash well and have a fairly aesthetic decor. You can easily find them in the texture you need.

MDF panels are ideal for bathroom cladding

Glass panels are more often used not as independent cladding, but as inserts. More voluminous areas can be seen in rooms with a specific purpose. They decorate the work wall in the kitchen or bathroom. Glass plates can be completely made of colored raw materials or have only a surface decorated with corrugation, photo printing, tonic or drawings.

Kitchen apron decorated with glass panels

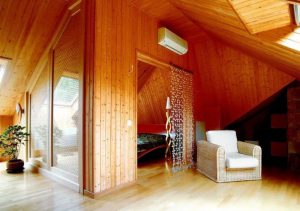

OSB boards have a special production method that provides for a cross arrangement of chip layers in the outer and inner layers, which makes them several times stronger than similar products made from MDF and chipboard. Despite this, powerful plates have excellent flexibility, which allows them not only to sheathe the walls, but to give the room a completely new look, somewhere by smoothing the corners, somewhere, on the contrary, by creating acute-angled protrusions.

Interior decoration with durable OSB panels

The non-standard structure of the OSB allows them to hold the screws well even when they are screwed again into an existing hole. The material has excellent water resistance, which significantly expands the scope of its use. OSB is most in demand in the decoration of attics.

OSB boards are popular in attic decoration

Oriented strand boards contain formaldehyde, so they are undesirable in rooms where a lot of time is spent, such as in the bedroom.

Magnesium glass sheet (SMP) is very good for finishing log walls. Reinforcement with fiberglass improved the flexibility of the material and increased the allowable radius of curvature of the sheets up to 3 meters. The risk of it breaking or cracking is minimal.

Magnesium glass sheet has excellent flexibility

SMP are light, fireproof, moisture resistant. They can not only decorate the walls in a country house, but also use them to create interior partitions of various shapes. The front side of the sheet is prepared for painting, laminating, wallpapering, etc. It does not need to be pre-putty and primed.

Block house

In appearance, the block house resembles an ordinary board, only with a convex cylindrical shape of the front side and non-standard processed ribs, which allow you to quickly mount individual elements into a single sheet. Sheathing from this material will help maintain the unique microclimate inherent in wooden houses. Lamellas no thicker than 25mm are taken for interior decoration. For their fastening, a crate is designed.

Wall cladding in a wooden house with a block house

Having decided to decorate a country house with a block house, you need to remember that this material is always purchased with a 10% margin.Naturally, these are additional costs, but if you buy it in insufficient quantities, you risk spoiling the decor of the entire room. The block house of different batches, like the wallpaper, differs in color shades, so it will be unrealistic to find an absolutely identical option to the purchased one. Adding lamellas from another series will significantly reduce the aesthetic result.

Block house colors

Wall cladding with a block house looks great, but requires maintenance. In the course of its operation, you will have to regularly clean the surface from dust settling on it and renew the varnish coating.

The disadvantages include the complexity of the sheathing process itself. Before starting to equip the frame, it is necessary to close up all the cracks in the wall of the log house and resolve the issue of laying a heat-insulating layer, which, in combination, will also become a sound wave damper. But with such a “puff” wall decoration in a country house it will always be warm and quiet. The sounds of the outside world will not disturb your peace.

Block house installation scheme

These minor shortcomings of the block house are offset by a whole list of advantages, including:

- high-quality ventilation;

- ease of installation;

- strength;

- healing effect.

Wall cladding with a block house is distinguished by its strength

In addition, this type of finish can act as a link in the decor, combining into a complete composition, the beams and forging elements present in the interior, for example. Wall cladding with a block house is aesthetically self-sufficient and in itself, without additional inclusions, because it looks like a surface chopped from logs.

Wall cladding with a block house is self-sufficient

Decorative stone lining

Active use of decorative stone in the interior design of country houses made of wood began not so long ago, although it looks very interesting on their walls. His presence can set the tone for the whole setting. Most often they are decorated with frame houses and buildings made of glued laminated timber, but they rarely work with decorative stone in log cabins and rooms with walls made of rounded timber. This is due to the fact that its plates require fastening exclusively on a flat surface.

Decorative stone in the interior design of a wooden house

As for the quality of such sheathing, in addition to high aesthetics, it is characterized by strength and practicality. She will last a very long time. Since the material is waterproof, it can be used not only in the decoration of halls, living rooms and halls, but also in the design of bathrooms, kitchens, indoor pools and other areas of the house with high humidity.

Wall cladding in a wooden house with durable decorative stone

Plastic in the decoration of the walls of a wooden house

Plastic is a practical and externally attractive material that allows you to very accurately finish the surface. It has an acceptable price. Basically, such cladding is used in wooden houses: in hallways, bathrooms, kitchen areas.

Bathroom wall cladding with plastic panels

In addition to the fact that plastic is moisture resistant, it is also very practical. To clean surfaces from it, you do not need to use expensive abrasives. They can easily be put in order by simply wiping with a damp cloth.

Plastic panels are easy to clean

Plastic sheathing is not difficult to install. You can do it yourself, without involving specialists, which is also important with a limited budget.

back to index ↑Features of sheathing wooden walls in wet rooms

When finishing rooms in a wooden house where a microclimate with high humidity is expected, only materials that can withstand its effects should be used for wall cladding. On those surfaces that will not be in direct contact with water, moisture-resistant drywall or Quick Deck boards can be used as a finish.Those walls where water will enter frequently and in large volumes, it is better to hide behind plastic, decorative stone slabs or ceramic tiles.

Moisture resistant Quick Dec plates

It is important to saddle the skin tight so that the wooden walls hidden behind it do not rot and bloom from water leaks. It does not hurt to pre-treat their surface with moisture-proof compounds. When decorating walls, special attention is paid to areas located behind the bathroom, toilet bowl, and adjacent sinks.

back to index ↑When do interior wall decor work begin?

“It’s better not to rush and let the new building stand for at least 10 months”

Finishing the house of a “fresh” log house can be started no earlier than the shrinkage process is completed. For a building made of glued laminated timber, this period lasts about four weeks, for the rest it stretches for many months. To calculate the time required to shrink a new house, you need to know the percentage of moisture content of the raw materials used for construction, the climatic features of the area where the cottage is placed, and take into account the duration of construction. In any case, it is better not to rush and let the new building stand for at least 10 months. During this time, the logs themselves will dry out, and the insulation lying between the crowns will die. Outwardly, it is difficult to notice the ongoing processes with the eye, however, if you neglect the recommendations and sheathe the walls before the end of shrinkage, then you can clearly see that it is quite active. The finish will definitely warp, cover with a network of cracks, or even tear it completely. In general, nothing will save you from rework, even the arrangement of a floating frame.

back to index ↑Conclusion

How and how to sheathe the walls in your wooden house is up to you, but remember that you can count on a pleasant-looking environment only if the process of decorating them is done correctly from the first steps.

Photo gallery - wall cladding in a wooden house

Video