The functional and decorative qualities of the structure connecting the two floors are equally important. The ladder should provide a convenient, safe ascent and descent. In addition, it is the main piece of furniture. Therefore, the design must be harmoniously entered into the design, made a profitable accent.

- Features of the screw design

- Pros and cons of stairs

- Materials in spiral staircases

- Features of wood structures

- Advantages of metal stairs

- Combined screw structures in the interior

- The possibility of making stairs with your own hands

- The main elements of a spiral staircase

- Basic requirements for screw design

- Selecting and creating a support

- Creating steps

- Production of balusters, racks and railings

- Stages of installation of the structure

- Optimal options for fixing stair elements

- Finishing the finished staircase

- Photo gallery - spiral staircase

- Video

One of the popular options in modern country cottages is a spiral staircase. This design has many advantages. Differ in variability, allowing you to make the perfect choice for any home.

Features of the screw design

The design of such a staircase, due to the radial placement of the steps, is similar in structure to a threaded screw, which is reflected in the name. Its main feature is compactness. The absence of marches significantly reduces the area required for installation. There are many types of spiral staircases. They differ:

- support types;

- materials;

- element sizes;

- number of turns, etc.

The structure may have one central support. If the layout allows, steps can be fixed on the walls. Spiral staircases with several supports are installed, structures without racks.

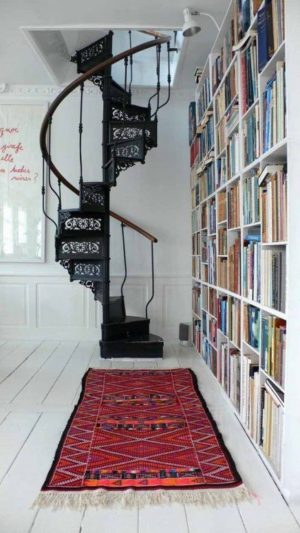

A spiral staircase will save space

Now in the installation of structures used a lot of different materials. The choice depends on the magnitude of the load, interior features, financial capabilities. The structure of the structure, the length and width of the steps are also selected individually. However, there are developed standards for screw structures. They need to guide the design. This will allow you to make a safe, reliable ladder.

back to index ↑Pros and cons of stairs

Before ordering the installation of a structure by specialists or creating a spiral staircase with your own hands, you need to carefully study the pros and cons inherent in such structures.

The benefits include:

- rational use of the area of the room;

- economical consumption of materials;

- original look.

The screw model is the best option for a small room that does not allow the installation of a traditional mid-flight structure. The variety of designs, the possibility of developing an individual project make it possible to create a staircase in any room.

The spiral staircase is ideal for small spaces

The absence of marching platforms allows you to spend material in minimal volumes.Much less money is spent on ordering or independently creating such a staircase than on other options.

Any screw design is exclusive, interesting, guarantees the originality of the interior. The ability to choose the shape, size of the steps, the number of turns, materials is a guarantee of creating a staircase that will adequately complement the environment and create maximum convenience.

These structures also have disadvantages that should be considered when choosing the type of stairs. Screw design:

- requires careful, competent design;

- creates inconvenience when lifting things with large dimensions;

- not suitable for intensive use.

Only a structure erected according to a well-designed project can ensure reliability and safety. You should not build a spiral staircase with your own hands from wood, metal, other material, if you do not have the skills and experience in creating such structures.

A spiral staircase will add originality to any interior.

It will be difficult to deliver a bed, wardrobe or sofa to the second floor through a spiral staircase. It is necessary to take this factor into account when erecting such a structure, purchasing furniture. Practice shows that if necessary, many times a day to make descents and ascents on screw structures, there is a feeling of discomfort, dizziness, and other negative symptoms are not excluded. You can install a ladder if the second floor is occupied by bedrooms that you do not have to enter repeatedly.

back to index ↑Materials in spiral staircases

An important criterion when choosing a ladder is the material. The strength and durability of the stairs, installation technology, cost, compliance with the style of the interior depend on it. The main types of building materials are:

- metals;

- tree;

- plastic;

- glass.

Air glass spiral staircase

They can be combined in order to give the desired aesthetic and functional performance. For example, metal elements with high strength are used in places of increased load, plastic can duplicate various parts of the stairs, providing practicality and durability. Glass is increasingly being used in the creation of modern structures. The increased strength of the tempered material, triplex, makes it possible to produce reliable glass steps.

back to index ↑Features of wood structures

Wooden stairs are very popular. This natural material has unique properties, has:

- strength and resistance to stress;

- durability;

- the ability to bring warmth and comfort into the atmosphere.

The wooden structure retains its qualities for many years. Modern impregnations give wood maximum resistance to moisture. Microorganisms do not multiply in the material, bark beetles do not start. Warm colors, beautiful texture guarantee the construction of impeccable aesthetic performance.

A wooden spiral staircase will bring an atmosphere of warmth and comfort.

Every craftsman who has the skills to work with this material will be able to create a spiral staircase made of wood with his own hands. Installation does not require complex professional equipment.

These designs can be considered universal, they are able to decorate any design style. The wooden structure perfectly complements the classics, country, rustic, Provence, Scandinavian designs. If you combine wood and metal, you can make designs that fit well into modern, minimalism and even loft. Wood has many shades, it is possible to successfully choose the material for a particular interior.

Wooden staircase will suit any design style

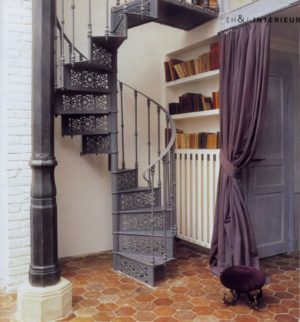

Advantages of metal stairs

In terms of strength and durability, metal is the absolute leader. This material is able to withstand increased loads, any external influences without losing its properties.In the creation of spiral staircases, various alloys are used:

- carbon steels;

- aluminum;

- stainless steel;

- cast iron.

Metal is able to withstand increased loads

Steel structures have an optimal ratio of quality and price. In order to provide reliable protection against corrosion, giving excellent aesthetic qualities, the elements are coated with powder dyes. An extensive palette of shades makes it possible to accurately select the option for the interior. Chrome plating, nickel plating can be used, providing protection against corrosion, beautiful shine.

Chrome-plated spiral staircase for interior in modern style

An important advantage of aluminum structures is their low weight. Even an overall spiral staircase will not create a high load on the load-bearing elements of the building. It is a durable material with maximum resistance to corrosion.

In modern interior styles, stainless steel structures harmoniously look. Such a staircase will perfectly fit into high-tech, minimalism, loft, eclecticism.

back to index ↑Combined screw structures in the interior

In the creation of screw structures, combinations of various materials are often used. For the most part, metal elements are used in the form of supports, railings. Balusters are made of steel, aluminum, artistic cast iron forging, etc. Stairs that combine metal and wooden or glass elements look spectacular.

The choice of combinations largely depends on the design style of the interior. Combination of wooden steps:

- with elements of artistic forging are used in the classics;

- with openwork metal fences are used in Art Nouveau and Provence;

- with laconic steel railings complement the minimalism.

The combination of metal and wood in a spiral staircase

An ideal option for high-tech is a spiral staircase with supports, stainless or chrome steel railings and steps made of plexiglass, triplex. These designs look original, give the atmosphere lightness, spaciousness.

Instead of expensive wood, in the manufacture of structures, elements from plates, plastic, imitating natural materials, can be used. The steps are decorated with laminated film, artificial veneer, polymer tiles.

The combination of chrome steel and glass gives lightness to the atmosphere

The possibility of making stairs with your own hands

Often, home owners order professional craftsmen to create such a design. But the owners, who have locksmith, carpentry skills, who have the necessary tools and equipment in their arsenal, can build a spiral staircase with their own hands.

The set of tools depends on the type of structure, the materials from which it will be created. The work will require universal devices:

- drill or perforator;

- angle grinder;

- building level;

- set of keys and screwdrivers;

- a set of dowels or anchors.

Drawing of a wooden spiral staircase

Only home craftsmen who know how to work with a welding machine can make a spiral staircase from metal with their own hands. You can invite a specialist to perform these works.

Before proceeding with the development of a project for a future structure, it is necessary to carefully study the features of its elements and perform several important calculations. This will give the stairs the necessary comfort and safety.

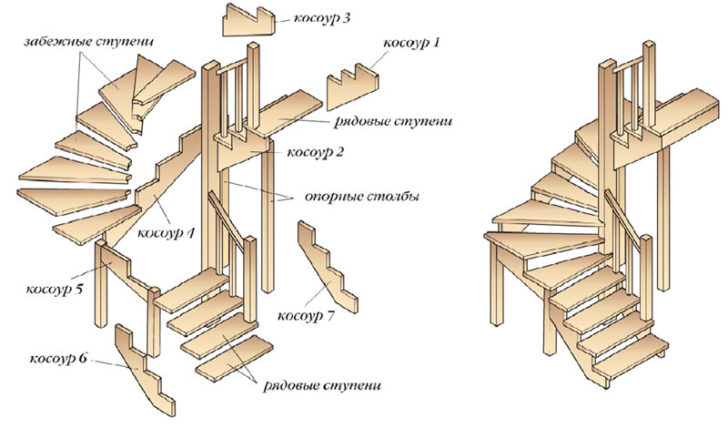

back to index ↑The main elements of a spiral staircase

Screw structures can have a different design. The standard set of elements includes:

- support in the form of a pillar made of metal, wood;

- steps;

- balusters;

- railing;

- jumpers;

- fence for the second floor.

An example of the construction of a spiral staircase

Forms, sizes of elements can be different, depending on the specifics. It should be noted that the height of the room in which the structure is installed must be more than two meters.In the structure of such stairs, risers are usually absent. These elements can interfere with optimal, safe placement of the foot on the step. Their absence not only makes safe, convenient operation, but also has a positive effect on the design. A staircase without risers looks light, airy, and the effect of overloading the interior is eliminated.

back to index ↑Basic requirements for screw design

It is advisable to entrust a professional specialist with carrying out calculations, developing a project. But if you decide to create a spiral staircase made of metal or wood with your own hands, you must take into account the basic requirements that a reliable, safe model must meet. The main optimal dimensions of the structure are as follows:

- step width 0 20 cm;

- step length - 80 cm;

- distance between steps - 15-20 cm;

- turn size - 12 steps;

- support diameter - 6-8 cm;

- coil height - 170-200 cm;

- opening diameter on the 2nd floor - 2 m;

- the total number of steps is odd.

This data can be used as a guideline. Depending on the type of construction, features of operation, they may vary. For example, if you do not have to use the stairs often, the length of the steps can be 50-60 cm. If necessary, create a full-fledged structure that allows you to conveniently carry even bulky items, this figure can be increased to 3 meters.

Distances between steps can be calculated individually. The main guideline for this is the height of a person, the optimal step length. If there are children, elderly people in the house, the distance between the elements should not be large. This will create a risk of injury.

Stylish spiral staircase without railings

Not always in modern designs of spiral staircases there are railings. Their absence gives the building a stylish, interesting look, the interior is light, a feeling of spaciousness is created. But such a solution cannot be used if children, sick people will use the stairs.

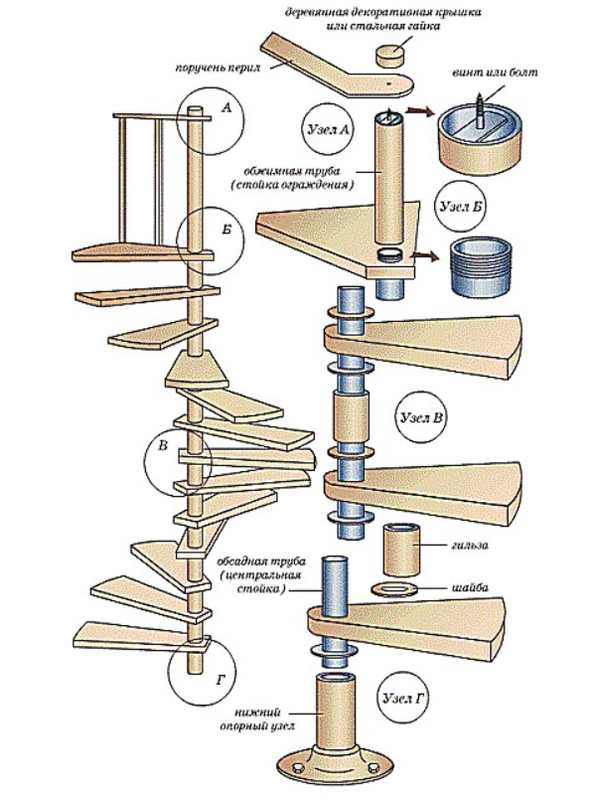

back to index ↑Selecting and creating a support

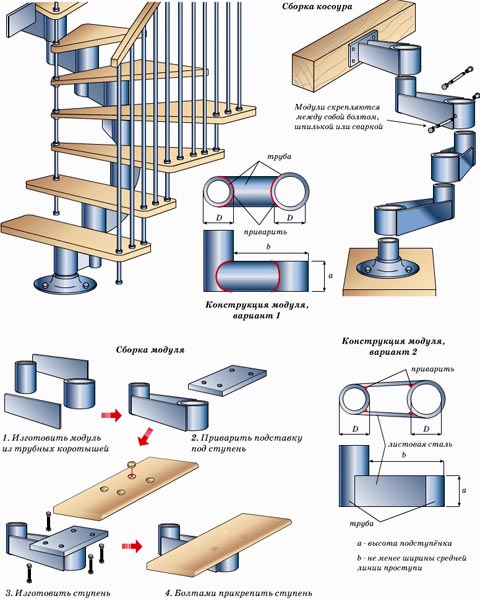

For the most part, steel pipes are used as supports for such structures. For this, rolled metal with a diameter of 6-8 mm and a thickness of 5 mm is purchased. These indicators provide the support with the necessary strength, the ability to withstand optimal loads. Bolts and couplings are welded to metal poles to fasten the steps.

You can use in the construction and other types of supports. The basis for a spiral staircase can be a pillar:

- wood,

- brick,

- concrete.

Looks harmonious design, completely made of wood. This is the best option for a cozy country or rustic, Scandinavian, eco style. The rack made of this tree provides a large number of types of fasteners. The steps can be fixed on metal corners, bars, etc. In making a wooden spiral staircase with your own hands, you do not need the services of a specialist welder, which reduces installation costs.

Spiral staircase made entirely of wood

Regardless of the material chosen for the support, you need to carefully calculate the load that will fall on this important element. In addition to the mass of all the elements included in the design, the weight of a person of solid dimensions and large luggage is taken into account. A guarantee margin is added to the final load.

back to index ↑Creating steps

Convenience, safety of using the stairs directly depends on the size and shape of the steps. Their production is given special attention. Specialists initially create a template according to which structural elements are made.

In the creation of wooden steps, you need to use wood with a high density that can withstand heavy loads. Good options are oak, larch, beech. There are several requirements for wooden steps:

- the material is used in the manufacture with an optimum moisture content of not more than 16-18%;

- the tree must be treated with special impregnations;

- the thickness of the board should be 5-6 cm;

- the last top step should be oversized.

The ease of use of the stairs depends on the size and shape of the steps.

These elements may take various forms. The classic option is a rectangle. But in spiral staircases steps in the form of triangles, trapezoids are often used. In the manufacture of such parts, it should be remembered that in the middle zone the width should not be less than 20 cm. Otherwise, using the stairs will be inconvenient and unsafe.

In the creation of metal steps, sheet steel metal is used. A template is also used to make elements. The thickness of the sheets is selected taking into account the magnitude of the load.

back to index ↑Production of balusters, racks and railings

Many home craftsmen who make spiral staircases with their own hands acquire ready-made balusters. Curly elements carved on special machines look perfect in wooden structures. You can make them yourself, if you have the skills, experience with wood.

In metal structures, the shape of the balusters is chosen according to the style of the staircase. It can be laconic rods, if the structure should fit into minimalism, high-tech. In the classic versions, cast-iron elements of artistic forging, industrial imitations of forged structures are popular. Metallic lace looks elegant.

Spiral staircase with wrought iron balusters

The racks connecting the steps can have a different shape. Cylinders are standard. Carved elements are used in wooden structures. These products can also be purchased ready-made from workshops specializing in woodworking.

In spiral staircases, the railings have a complex structure. It is quite difficult to do them on your own. Curved wooden elements can be created by professional craftsmen who have special equipment in their arsenal. If you have to make a model with your own hands, the following technologies are used:

- gluing railings from thin sheets of veneer;

- sawing out small parts for subsequent assembly;

- creation of a structure from glued bars.

In the creation of metal stairs, pipes are used that are welded to the balusters. You can use wooden railings to improve aesthetic performance, comfortable use.

Railings from pipes welded to balusters

Stages of installation of the structure

Installation of the stairs is carried out in several stages. The order and type of work depends on the specifics of the structure, materials of manufacture. The construction of a standard wooden structure is carried out as follows:

- the location of the stairs is determined;

- marking is performed in the form of a circle on the floor, where a passage to the upper floor will be created;

- using a plumb line, a symmetrical point of the center of the circle on the floor is determined, which is the installation site of the support;

- the required opening is cut in the ceiling;

- the edges of the opening are formed;

- the ladder support is mounted;

- fasteners for steps are fixed;

- on the floor a basis is created for the lower step;

- the last step is fixed on the floor of the second floor;

- all other steps are mounted;

- balusters are installed;

- marking is carried out, balusters are cut at the right angle;

- railings are fixed.

Optimal options for fixing stair elements

The strength and safety of this structure largely depends on the quality of fastening. When creating a spiral staircase made of metal or wood with your own hands, this nuance needs to be thought out in advance, to purchase the required consumables.

There are several important components in the design that should be given special attention.These are the connections:

- fences on the top floor with a support;

- supports and steps;

- bottom and top steps with support.

In the first case, a bolt is installed in the back of the support, a handrail is mounted on it, in which the desired hole is made. The fixation and masking of the connection is provided by a decorative cover.

Stages of assembling a spiral staircase

For a strong fastening of the steps on the support, you can use sleeves, washers that are put on the pipe. The lower element is fixed on a special base, which is created on the floor. The upper step is fixed on the floor of the second floor.

back to index ↑Finishing the finished staircase

After completing the installation of the spiral staircase, you can proceed to the finishing work. All kinds of coatings perform a decorative and protective function. A competent choice of materials will make the design a worthy decoration of the interior, and ensure its durability.

In the modern assortment it is easy to find means for processing any surfaces. The metal elements of the stairs must be protected from rust if they are not made of stainless, chrome-plated steel. You can use strong, durable powder dyes. These materials are available in a wide range of colors, it is easy to choose an option taking into account the specifics of the interior.

Painting stairs has a decorative and protective function

Ordinary paints can also be used in painting metal elements. These materials do not require the use of professional equipment. Even a person who does not have the skill and experience can cope with staining. A wide range of products guarantees an excellent choice.

Masking the unique texture of wood is not worth it. This is the main advantage of the material. Despite the impregnation of wooden parts, they require additional protection from moisture, the negative effects of dry air. For this, varnishes are used, which are applied in several layers. Varnishing will not only protect the tree, but also give the stairs a noble, respectable look.

Lacquering will protect the wooden surface of the stairs

Photo gallery - spiral staircase

Video