Have you bought a plot of land outside the city and even managed to build a nice house on it? It's time to start landscaping the rest of the territory. The first thing to do in this direction is to pave the garden paths. It will be more convenient, faster and easiest to do this using molds for the production of paving slabs. Alleys will turn out neat and will become a real decoration of the country landscape for many years.

Paving slabs are good not only in the design of paths. With its help, you can make a blind area around the buildings, lay out a platform for a recreation area and a parking lot. In addition, self-made tiles can have an original shape and pattern, so that the territory of your site will never look standard and inspire melancholy.

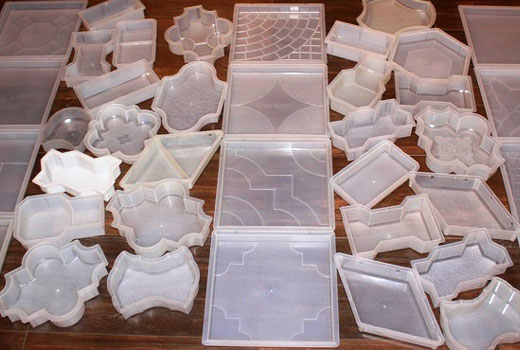

Using the mold, you can make a tile of the original shape

The production process is uncomplicated. The main thing is to make or purchase a successful blank for ebb, and for this you need to at least know what kind it can be.

back to index ↑Types of paving slabs

Tiled masonry is at the peak of popularity today, so it is not surprising that the material is presented in a wide assortment variety. Basically, it differs in design and production method. Most often it is given the form:

- rectangle;

- rhombus;

- square.

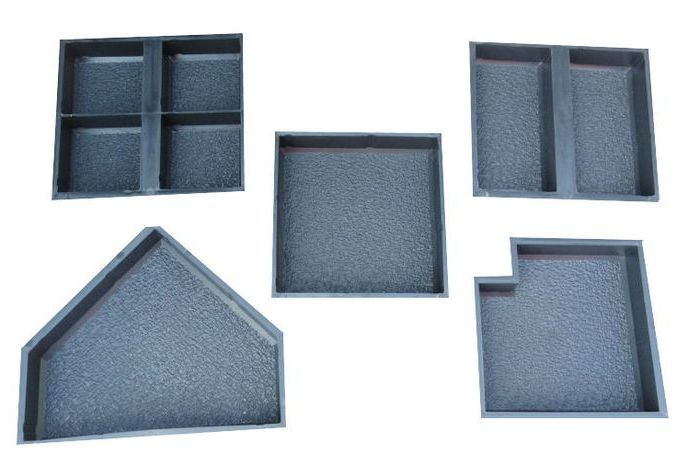

Forms for square paving slabs

Universal paving stones and modular tiles are in great demand.

As for the production technology, the tiles can:

- Cast.

- Press.

The latter is produced exclusively in the factory, but the first is not difficult to make at home. All that is required in the work is a special form and concrete mortar.

It is not difficult to make a tile on your own using a mold

Ready-made forms for pouring paving slabs: types and characteristics

Today there is no shortage in the range of such products. They can be purchased by both amateurs and professionals working in the field of large-scale production of paving slabs. They go on sale in sufficient quantities.

The problem lies in the quality of the forms themselves. Since they are made from a variety of materials, their performance characteristics vary markedly. For the production of forms today goes:

- Polypropylene.

- All kinds of plastic.

- Polyethylene.

- Rubber.

- Polyurethane.

- Silicone.

You need to be especially careful when purchasing plastic derivatives, as there are often molds made from recycled materials. It is difficult for a non-professional in the construction business to distinguish them, but if you know what to look at, then you can.

When buying a mold for paving slabs, pay attention to the material

A not very high-quality product has a rough surface and an unattractive appearance due to the lack of gloss and chips and other flaws that are clearly visible to the naked eye.Before pouring the working solution into such a form, it will definitely have to be additionally lubricated. There will be problems with the extraction of the finished tile. You can’t get it if you don’t steam the workpiece in hot water. The manufacturer does not provide guarantees for such instances, therefore, one cannot count on long-term service. The only thing that can somehow compensate for the existing shortcomings is a loyal price. Let's see what the other offers are.

Rubber molds for paving slabs

These types of molds are not in great demand, as they are quite heavy, expensive and difficult to operate. To work with them, you will need special equipment in the form of a vibrating table, a drying rack and portable shields, with the help of which the workpieces will be sent to the drying place. The purchase of rubber options is not very justified even for a business, as it requires a solid investment. In addition, the production of rubber itself is constantly becoming more expensive and, in order to keep a competitive price for the material, manufacturers begin to add soot to it, that is, to body the original composition. Naturally, this reduces the quality characteristics of products made from rubber, in addition to everything, paving slabs from such a form may come out in a dark color, as they will be painted with soot present in the material. It will be impossible to produce in rubber molds for paving slabs and something original, non-standard configuration.

Rubber molds for the production of paving slabs

After use, the forms will have to be washed with hydrochloric acid, which, to put it mildly, is not a pleasure, and everything has a bad effect on health. In general, if hand-made work on casting tiles is expected, then it is better to take a closer look at the blanks in a more modern design.

sheet plastic products

The concept of sheet plastic includes:

- PVC;

- polystyrene;

- acrylic;

- ABS.

They are stamped on special thermal vacuum machines, by vacuum molding.

PVC plastic

“This type of mold for paving slabs makes making blanks a little easier with your own hands”

It is presented in different variations. The least practical forms are obtained from the film variety. Their walls are thin, so it will be necessary to move the workpieces filled with mortar into the drying zone exclusively on the shield. You need to make sure that the form is not deformed, so you will almost always need to use a stand.

After use, the containers are washed in soapy water to avoid concrete sticking. It takes a lot of time. But even the most careful care and careful operation do not saddle the film forms with durability. After 15-25 fillings, they become completely unusable, so it is not profitable to take them for large volumes of work.

Two-millimeter PVC plastic is a more durable option, however, the wall thickness declared by the manufacturer of 2mm is often just a publicity stunt. In reality, this figure barely reaches 1.5 mm.

Molds for paving slabs made of PVC plastic

This type of mold for paving slabs makes making blanks a little easier. It will also require the use of coasters and specific equipped places for drying. Nothing should put pressure on the filled containers. In order for the concrete not to stick in the form, it must only be used clean and the concrete solution must be kept in it for at least two days, that is, until completely dry.

In terms of strength, thickened PVC plastic is superior to film plastic, although it tends to burst. The form from it will withstand up to 70 fills.

ABS plastic

Forms from such material meet the standards, but with their help it is customary to make larger concrete structures such as fences, columns and other things. As for paving slabs, it will be difficult for her to give even outlines in such containers.The presence of rounded contours will greatly complicate the subsequent laying of the elements, since quite noticeable gaps will form between them. Tiles that are not joined organically will never allow a path or a playground to look aesthetically pleasing.

You have to give credit to the products. The tile cast in them has a gloss, however, it will need to be kept in molds for up to two days. After use, the latter are thoroughly washed from adhering concrete.

ABS tile molds

If the offer seems interesting, then it is not superfluous to deal with the selection criteria. A good ABS shape will never be in a dark color. Such shades are the prerogative of low-quality plastic made from recycled materials. The low-grade CSB is thin on the bends and the product from it, even with a slight deformation, emits a suspicious crack, while good plastic will not burst on the twist.

Silicone molds for paving slabs

This is the most popular form model. They love to work with because of the ease of use. Products are elastic. They make it possible to display the smallest details of the pattern on the cast tile. With the help of silicone, you can make an imitation of an artificial stone. However, mass production of tiles in silicone molds is not justified, since the containers do not have a large margin of safety, despite the fact that they belong to the middle price segment. But for home use, they are simply irreplaceable. You can easily make an unusual design tiles, which in turn will become the highlight of the garden.

The silicone mold will allow you to cast the tiles of the original shape

Polyurethane

Good quality polyurethane molds are durable. They are durable, so they can be used in bulk production. Such blanks perfectly convey the texture, so that at the output they get an excellent imitation of a boulder and natural stones. Polyurethane forms are indispensable in the manufacture of paving slabs with your own hands. The only thing that makes you think about the choice is the price of products.

Polyurethane molds are durable

Formoplast

Today, this version of the forms is not in demand. Disposable products. It is rare to use them for more than one fill. Provided that even the smallest country alley requires far more than 10 tiles, it becomes obvious that such an acquisition is extremely unprofitable. Even the low price of blanks does not save the situation.

Polystyrene

Forms for pouring high quality paving slabs are obtained from it. The containers are able to perfectly convey the texture of marble, not only in the pattern, but also in the splendor of brilliance, which makes paving slabs a real exclusive.

Polystyrene molds are easy to use. They do not need to be soaked and washed after pouring. The tile comes out of the container easily.

Polystyrene molds do not need to be soaked and washed

Be careful when buying. High-quality polystyrene forms are protected by a film on the inside. If there is none, it is most likely a fake.

fiberglass

Such forms are used in the production of three-dimensional slabs and small garden forms. With their help, you can not only cast overall tiles for paving paths, but also figures for garden decoration and landscape decoration. In work, fiberglass products are not very convenient. They require pre-lubrication prior to use, which can sometimes cause pores and even cavities in the molded parts. They will not have a glossy sheen. Sometimes, after being removed from the mold, the tile has to be modified. After analyzing the above, it is easy to conclude that fiberglass molds are not the best solution.

Fiberglass molds require prelubrication

How to choose a practical form for casting paving slabs?

The quality of products of this kind is directly proportional to the quality of the material used for their production, as well as the status of the manufacturer. The priority should be the products of large, well-reputed enterprises that have been presenting their products on the market for several days.

As for the materials, it is worth taking a closer look at the forms of primary polyethylene. They are distinguished by the correctness of the contour, good rigidity, the absence of deformations and cracks. According to experts, such forms for the production of paving slabs are ready to withstand about a thousand pours of concrete..

High-quality forms will withstand about a thousand pours of concrete

Derivatives of secondary polymers are no less good in operation. The tile cast with the help of such forms will receive ideal geometric proportions and will delight with the clarity of the pattern. The strength reserve of forms is designed for 500 fillings. However, one must be vigilant when purchasing copolymer "blanks". Unscrupulous manufacturers under their guise can exhibit products from cheaper secondary raw materials. Naturally, their characteristics will be far from those described. Knowing the following factors will help you avoid mistakes. Good molds made from recycled polymers do not crack when compressed, and their surface is always shiny.

Recycled resin molds for 500 pours

What else is worthy of attention is granulated polystyrene blanks. Forms have proven themselves remarkably in home production. Each of them is capable of producing up to 100 paving slabs, while they will receive the perfect geometry and gloss on the surface. True, it will take about 2 days to withstand the concrete in the forms, but no one is in a hurry, right?

And the last recommendation. Before buying a form, be sure to study the quality certificate for it. In it you will find accurate information about the raw materials used for its production and other important characteristics.

back to index ↑Making a mold for paving slabs with your own hands

Instead of spending money on dubious quality blanks for the production of paving stones, you can work on their creation with your own hands. This is a great way to save money and a chance to make the territory adjacent to the house original and unique. To make a blank, sometimes you don’t even need to spend money, since improvised materials are quite suitable for this.

There are many design ideas for molds for casting paving slabs. The choice of consumables is also varied. At home, the molding container can be made:

- from wood;

- gypsum;

- metal;

- silicone;

- polyurethane.

You can make your own tile mold

What is good about each option?

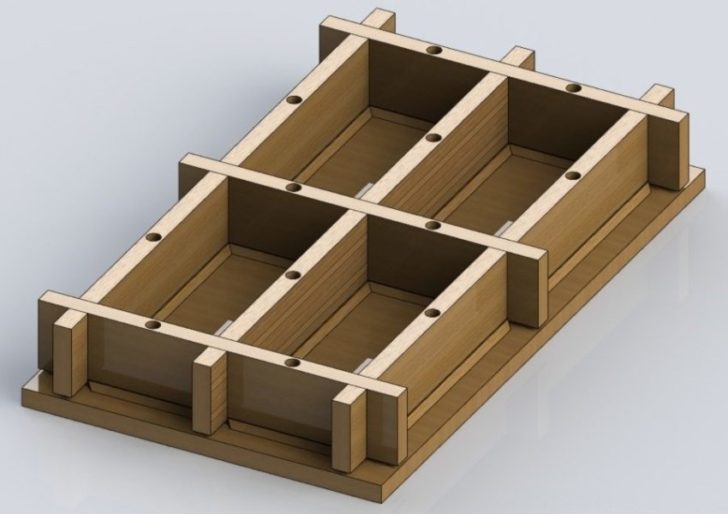

Tree

Wooden formwork is the most affordable way to cast tiles at home. Assembling it with your own hands is easy. In work, you can take not only boards, but also moisture-resistant plywood. The formwork can be adapted for loading into the machine used for the production of vibrocompressed products at home.

An example of making a mold from wood and a rubber mat

To assemble the form, you need to prepare not too thick strips. Structural elements will be cut from them, which will later be assembled into a workpiece with the help of nails. Do not try to hammer fasteners tightly. It would be more correct to leave it in free motion, so that when the tile is removed, the formwork can be removed without problems. Wooden molds are ideal for producing simple tiles in standard configurations and clear shapes. You can't count on something exotic with this approach. For the ebb of the original tile, you need to look for other options.

Miracle plastic

The most budgetary option that allows you to build a blank for casting tiles from plastic bottles that are indispensable in the household. The most demanded in our case is a five-liter container.

Plastic containers are suitable for casting tiles

To make a mold, it is enough to cut off the bottom of the bottle. This must be done at such a height that paving slabs are needed. In principle, a container for pouring concrete mortar can be: trimmed canisters, food packaging and other items that are suitable in shape and size for your project.

Gypsum

“Gypsum molds for paving slabs can be made even by people who are very far from construction”

A popular idea, often implemented in private practice. Gypsum molds for paving slabs can be made even by people who are very far from construction. Moreover, the gypsum model of the workpiece will make it possible to cast not only simple geometric specimens, but also figured tiles of any design.

For work, you will need a sample of the tile planned for production, formwork and gypsum mortar. Formwork can be a wooden structure, an old aluminum or plastic bowl, a piece of a car tire.

An example of a plaster mold for making tiles

Before proceeding to the production process of the blank, the sample of the tile is covered with a layer of fat. This is a necessary measure that allows you to easily remove the part from the mold in the future. The next step is to place the prepared part in the formwork and fill it with gypsum mortar. It must be prepared exclusively before pouring, as gypsum is prone to quick setting. To increase the strength characteristics of the future form, it is recommended to introduce additives such as plasticizers or cement into the working solution.

It is necessary to pour the finished gypsum mortar so that the tile lying in the formwork is covered with it by at least 2 cm.

Although gypsum tends to set quickly, you should not rush to take the mold out. Let her stay for a day. In this case, you will get a clear imprint of the workpiece, reflecting the smallest details of its decor.

Criticism of gypsum molds for paving slabs for their fragility is undoubtedly justified. With active use, bumps and falls, the shape may be damaged. But this is not a reason to discount the idea, because the cost of manufacturing a new blank is minimal.

Metal

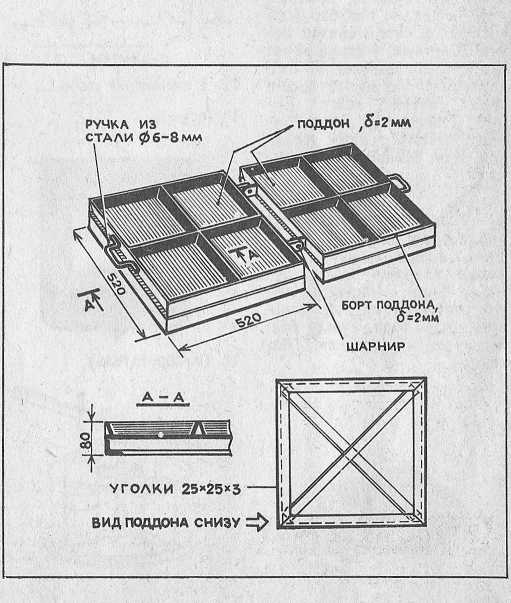

It makes sense to make forms from metal if large-scale work on the production of paving slabs is coming. Assembly will require the use of a welding machine, although today more and more often they are trying to make blanks collapsible, since metal is not inherent in flexibility and when a finished tile is knocked out of the mold, there is a high risk of damage to the concrete product.

There are several ways to assemble a metal mold. It all depends on the imagination of the master. It can be given the appearance of a square, hexagon, etc. But the result will be much more interesting if the mold for the production of paving slabs has a relief bottom that imitates the wood structure, the texture of stones, or simply carries a geometric pattern.. Finished products will look very colorful.

Scheme of a metal mold for paving slabs

If you don’t want to bother with welding and other tricks, look at the pipe cuts left after the construction of the house. It's great if they have different diameters. To get a blank for the ebb of the tile, it is enough just to cut the pipes into segments of the same width. Now it remains to fill them with a concrete composition and after a couple of days to remove nice round elements from the molds.

Forms for paving slabs from pipe scraps

You can lay tiles of various sizes in any order or by creating a specific pattern. It will be interesting to look at the path paved with multi-colored tiles. To get it, just add dyes of the desired shade to the concrete.

Polymers

"Silicone molds for exclusive paving slabs are best made by yourself"

Polyurethane and silicone are considered the best materials for creating blanks for casting paving slabs.Using them, you can cast the most unusual elements in their design, which have no restrictions either on the configuration of shapes or on decorative details. Silicone molds for exclusive paving slabs are best done on your own. Is it possible? Quite! In stores there is a special mass that comes with a hardener. A model of the future form can be both a purchased tile, and laid out personally. If you want to get a patterned surface, place a pattern of sticks, wire, shells, beads on top.

Special mass for making molds

Next, you need to act according to the algorithm for working with gypsum. Mix the liquid mass with the hardener and immediately fill the tile laid in the formwork with the resulting composition. The base layer of the mold should be at least a centimeter thick. After setting, it will be necessary to cut off excess material from the upper surface, after which the workpiece is allowed to be removed completely.

The polyurethane mold is made in the same way.

natural gifts

Nature itself will help to make a tile of interesting design. Try to mold it in the form of, for example, burdock leaves. This idea will appeal to those who want to have paths that attract attention with their non-triviality in the country landscape.

Original tile in the form of leaves

To obtain unusually shaped elements, a thick layer of thick, moldable concrete mortar is applied to the burdock leaf, which is pressed tightly against the green base. After the composition dries, the tile is cut along the contour of the sheet. Such concrete “leaves” should be laid on the track at some distance from each other. The ideal walking distance is 20 cm.

The process of making tiles in the form of a sheet

Mandatory nuance

Whatever type of paving slabs you work with, they will certainly have to be lubricated before use. The lubricant must contain fats or oils. What is suitable for the role of lubricant?

- Working off.

- Fat of animal origin.

- Vegetable oils (palm, sunflower).

- specific lubricants.

Molds must be lubricated before use.

When choosing the type of lubricant, you need to take into account its side effects in order to prevent staining the tile in unwanted tones and staining it.

back to index ↑Conclusion

Self-made forms for paving slabs will help save a lot of money and at the same time allow you to get exclusive material for arranging the territory of a country house.

Video