It is very difficult to do without a change house in a country or personal plot - after all, this is the most convenient room for storing not only garden tools, but also all kinds of small-sized building materials and dry mixes.

- Types of change houses that are built with their own hands

- Homemade change house from OSB panels

- Do-it-yourself mobile change house with a pitched roof

- Do-it-yourself country change house from sandwich panels

- container change house

- Log cabins

- Do-it-yourself change house 3 by 3: estimate

- Do-it-yourself trailer

- Do-it-yourself bath from a change house

- Conclusion

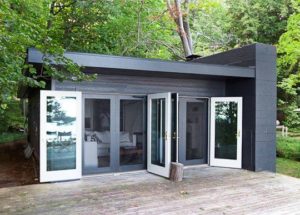

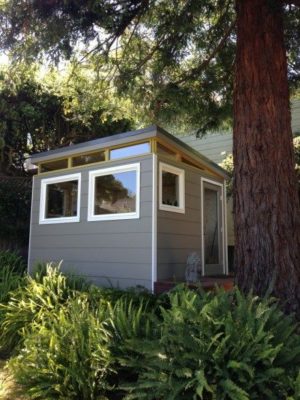

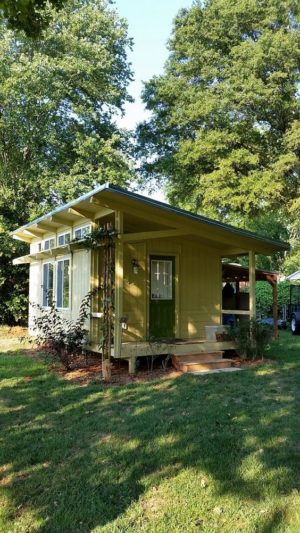

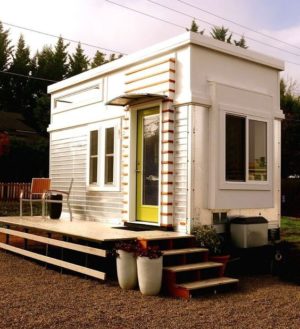

- Photo gallery - do-it-yourself change house

- Video

Today, without much difficulty, you can buy a ready-made plastic "house" for storing hoses and other shovels with pitchforks, but their price is by no means democratic. Building a change house with your own hands according to step-by-step instructions is much more interesting and cheaper, besides, its dimensions and shape in terms of plan can be made exactly as needed in this particular case.

Types of change houses that are built with their own hands

Do-it-yourself change houses according to step-by-step instructions are classified as follows:

- panel assembly;

- frame structures;

- from logs or timber;

- brick.

When deciding which type of change house to build with your own hands, one thing must be taken into account: for all of them, except for panel structures, at least a minimal foundation is required.

Panel structures

Panel prefabricated cabins are as simple and efficient as possible to manufacture, very cheap and completely short-lived - that is why they are almost always built as temporary structures. After they are no longer needed, they are usually dismantled, the resulting "spare parts" are used for firewood or, for example, for panel formwork.

Panel change houses are simple and efficient in manufacturing

Change houses of this type are ideal for use at facilities under construction, where they can play the role of not only a warehouse for building materials and tools, but also, in a suitable climate, even as temporary housing for workers.

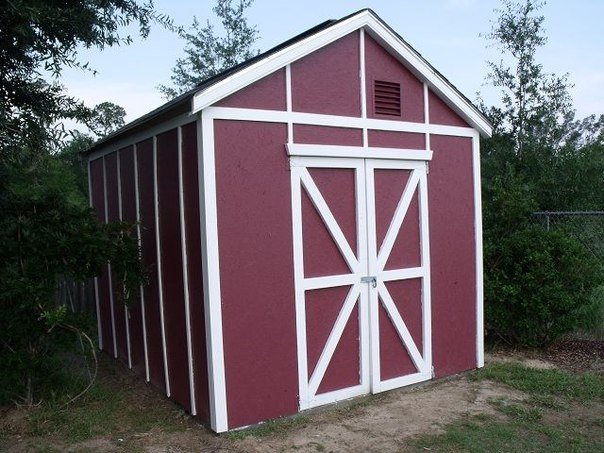

Frame buildings

Frame change houses - designs are more reliable and durable. Usually, in order to reduce the cost of construction, the frame is made of wooden bars or slats, although change houses with a metal frame have maximum durability. For wall cladding, any available material is used - OSB sheets, profiled sheet iron, lining board, if financially possible - sandwich panels.

Frame change house

Log cabins

Log cabins are the most durable and solid option. The cost of such structures is relatively high, but if necessary, they can even be used as living quarters. Do-it-yourself change houses have a wonderful decorative look, fit perfectly into any landscape design.

Log cabins have a wonderful decorative look

The main disadvantages of such structures are their cost and the need for at least a shallow strip or column foundation.

back to index ↑Homemade change house from OSB panels

“When choosing a place on the site for building a change house with your own hands, you should take into account that there should be a convenient approach to the building, but at the same time it should not interfere with gardening or construction work”

A change house made of OSB panels is one of the simplest and most affordable construction options. The list of materials that will be needed for work is minimal:

- crushed stone, sand, cement;

- metal or plastic fittings;

- OSB boards;

- wooden beam;

- roofing material for roofing.

Let's see how to make such a change house with your own hands according to step-by-step instructions.

Preparatory work

Work begins with clearing and preparing a site for a site (a kind of foundation) for a change house. Moreover, when choosing a place on the site for building a change house with your own hands, you should take into account that there should be a convenient approach to the building, but at the same time it should not interfere with gardening or construction work. In no case should it be installed in flooded lowlands, and one should not forget about the likely wind loads - frame change houses are very light structures. The traditional choice of the location of the change house is a free corner of the site.

Having chosen a place, mark the site, which is then leveled along the horizon. Then mark the outer boundaries of a small solid foundation for a change house. According to the marked contours of the future foundation, a few centimeters (10-15 is enough) are removed from the soil - in the resulting small "pit" a layer of sand is poured, then a layer of rubble. Crushed stone after pouring, it is desirable to lightly tamp with any means at hand. It is recommended to use ready-made sand-soil mixture only as a last resort.

Site pouring

Then, along the contour of the prepared area with a sand and gravel cushion, a formwork is set up, the height of which is determined by the planned height of the future floor level in the change house. You should not be too zealous, but making the thickness of the foundation slab less than 10 cm is also undesirable. Over the entire area, a mesh of reinforcement should be laid on the lining - it should be located approximately in the middle of the concrete layer.

Pour concrete evenly over the entire area

Concrete should be poured evenly over the entire area, preferably in one go. After pouring, while the concrete has not yet set, it is imperative to install several anchor ("foundation") bolts into it along the contour of the site - in the future they will greatly facilitate the work.

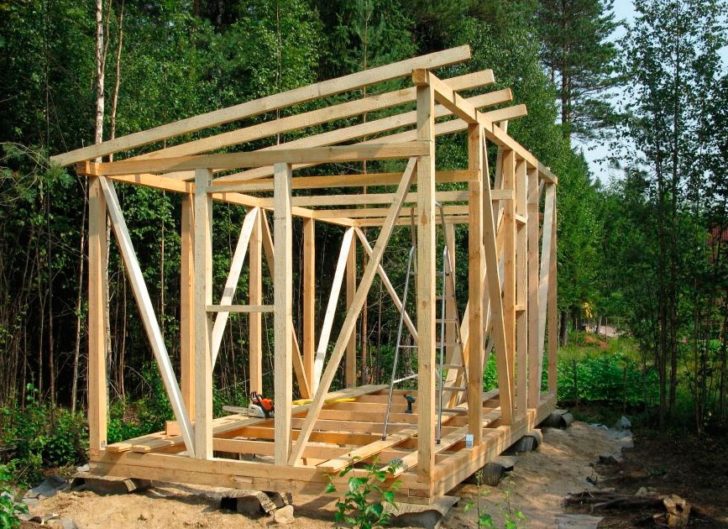

Frame assembly

After the concrete has completely hardened, four wooden beams of a small section are attached to the anchor bolts laid around the perimeter - 100x50 mm will be enough. It is on these boards, which play the role of mortgages, that the entire frame of the change house will be assembled - therefore, their fastening to the foundation should be as reliable as possible.

Place vertical corner posts in the corners

The next operation in the step-by-step instructions for building a change house with your own hands - vertical corner posts are set in the corners. They are necessarily set according to the level - in the future, these racks will be connected by the upper transverse beam, from which, in turn, the roof will “dance”. This work is quite difficult to do, especially if you work alone, therefore, to simplify the task, it is recommended to attach temporary supports to each rack from the outside. In any case, the racks should be attached to the bottom board using mounting brackets of the appropriate size.

Attach temporary supports to each rack

Installation of a gable roof

The most traditional roof for backyard change houses is a gable roof. With small sizes, it is done quite simply. First of all, truss beacons are mounted on both sides, then they are connected to each other by a transverse beam. Since all these connections are temporary, it is quite acceptable to use clamps for fastening.

Rafter beacons are mounted on both sides

Then rafters are attached to the beacons; for reliability, it is better to use special fasteners. Although, with the small size of the change house and, accordingly, its roof, it is quite possible to get by with nails.

Special fasteners for rafters

wall cladding

The most budgetary option for sheathing a frame change house is OSB-plates. They are produced in different sizes and thicknesses, so they can be used not only for walls, but also for roofs. These plates are quite warm, they are produced and sold already treated with antiseptic material, they are not at all afraid of moisture. If necessary, they are easy to paint in the desired color.

Covering the change house with OSB-plates

Roof and floors

After the wall cladding, it's time to start installing the roofing. For lining the roof of a do-it-yourself change house, you can use any available material, up to OSB sheets. However, much more often metal profiled sheet metal, painted or simple “galvanized”, is used.

Do-it-yourself change house from OSB panels

The latest operation for the manufacture of a frame change house is the painting of the building. The options here are very different, determined solely by the imagination of the owners. You can use ordinary facade paint, you can cover the walls with colored or colorless varnish, additional treatment with an antiseptic will not be superfluous. Cladding with clapboard, MDF panels, plastic siding is acceptable.

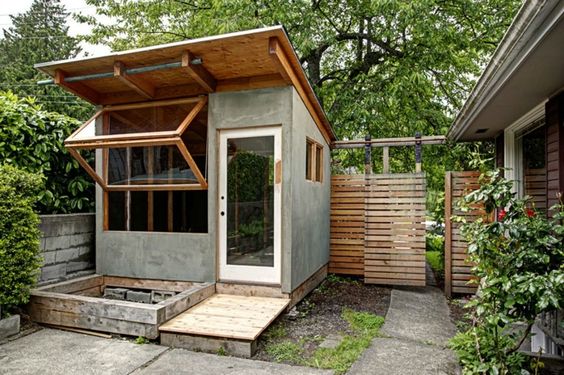

back to index ↑Do-it-yourself mobile change house with a pitched roof

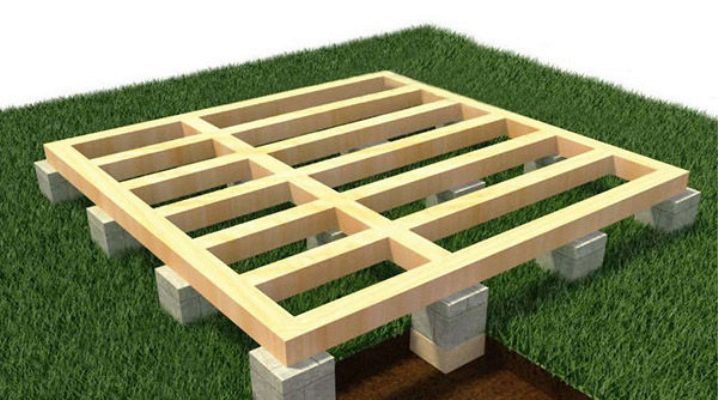

If it is not possible to pour a concrete foundation slab, you can build a frame change house using a different technology - but in this case, you will need several concrete blocks, preferably foundation ones. At the same time, to simplify the design of the entire change house as a whole, the roof can be made lean-to ("flat"). Let's figure out how to make a mobile change house with your own hands according to step-by-step instructions.

Site and foundation preparation

The site is prepared in the same way as in the first case - it is cleared and leveled. But there is no longer any need to cut the soil, since the house will be mounted on a strip foundation laid out of blocks. But layers of sand and gravel need to be poured out - they will, at a minimum, serve as a kind of drainage for the underground space. Outside, around the block foundation, it is necessary to make a small blind area - for this it is enough to give the soil adjacent to the outer side of the block a slight slope.

Strip foundation laid out of blocks for a change house

Frame assembly

Several layers of roofing material, which plays the role of waterproofing, are laid on the upper surface of the laid blocks, and a strapping of wooden beams is already applied around the perimeter. For this type of construction, the thickness of the beam should not be less than 100 mm - a smaller section simply will not provide the required guarantees of reliability.

Roofing material plays the role of waterproofing

This method of mounting a change house with your own hands has its advantages compared to the first method, in which the lower starting bars are rigidly tied to a concrete base. The main advantage is that the design is mobile, it is enough just to move it from one place to another. In addition, the presence of underground space guarantees the dryness of the floor. With additional wood treatment with an antiseptic, such a design will serve properly for a very long time.

Walls

Do-it-yourself wall installation at a change house with a shed roof, as in the previous case, begins with attaching corner vertical posts to the base. Then the installed bars are connected in the same way around the perimeter with horizontally arranged wooden jumpers. The finished frame is sheathed with the selected material.

Fastening to the base of the corner vertical posts

One point should be taken into account - since the roof will be shed, one of the walls must be made a little (usually about 0.5 m) higher than the opposing one. The difference in these heights will determine the angle of inclination of the slope, and the value of this angle depends on local climatic conditions: during heavy snowfalls, the slope should ensure free descent of snow from the roof; in warm southern regions, the slope can be symbolic, sufficient for rainwater to roll off.

Shed roof installation

The shed roof frame is one of the simplest building structures. Two extreme rafters are installed, then a construction cord is pulled between them. On this cord, with a step of approximately 0.6 m, intermediate rafters are evenly installed. For fastening, it is recommended to use special professional fasteners - plates, corners, brackets. Any roofing material can be used, usually it is slate or profiled sheet.

When calculating the length and installation of truss beams, one should not forget about the need for a device with raised and lowered small (20-30 cm) sides of the change house overhangs-visors. Above the front door, you can additionally make a small canopy.

Installation of roof beams

The floor in the change house with their own hands is made two-layer - rough and finish. Base bars are used as supports for the subfloor for small rooms; for a large area, it makes sense to add several intermediate logs. Bars of a small section are attached to the subfloor - logs for a clean floor. The space between them is sewn up with a windproof (vapor barrier) material and filled with any available insulation. Lastly, the flooring is laid - usually OSB sheets, plywood or planed boards.

The floor is filled with insulation

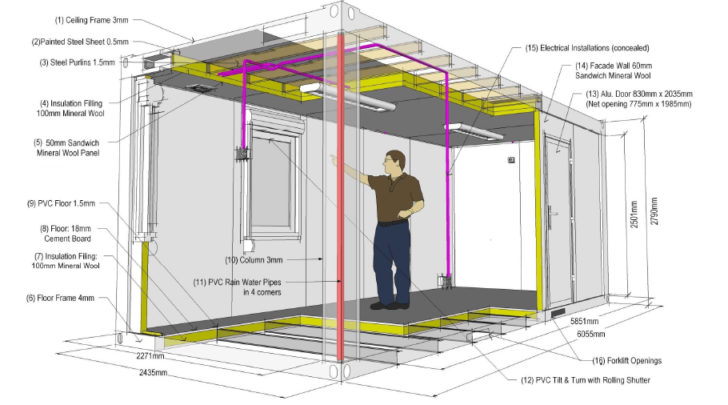

Do-it-yourself country change house from sandwich panels

“Assembling a country house from sandwich panels with your own hands is simple and not much more difficult than assembling something from the designer’s parts, so most manufacturers sell ready-made kits of panels fitted to the size”

Sandwich panels are a relatively expensive material, but it has a lot of advantages and is quite suitable for building a backyard change house. The premises made of such panels are very warm and light, the installation is quite simple, and therefore the “sandwich” is increasingly used to build not only change houses and makeshift houses, but also full-fledged residential buildings.

Sandwich panels provide excellent heat and sound insulation

All architectural elements of such change houses, including the roof, are made of panels that provide excellent heat and noise insulation, plus practicality and durability of operation. The only drawback of this material, as noted above, is its relative high cost. Accordingly, building such a house solely for storing shovels and irrigation hoses is, to put it mildly, unreasonable. But as temporary housing (for example, at a construction site or in the country), such a building justifies itself.

Now let's see how to make a country change house with your own hands according to step-by-step instructions.

Design and installation features

Do-it-yourself assembly of a country change house from sandwich panels is simple and not much more complicated than assembling any of the designer's parts, so most manufacturers sell ready-made kits of panels fitted to the size. It is enough to simply “twist” them together according to the attached instructions in order to get a full-fledged country house. However, even for such an easy-to-assemble change house, a foundation is needed.

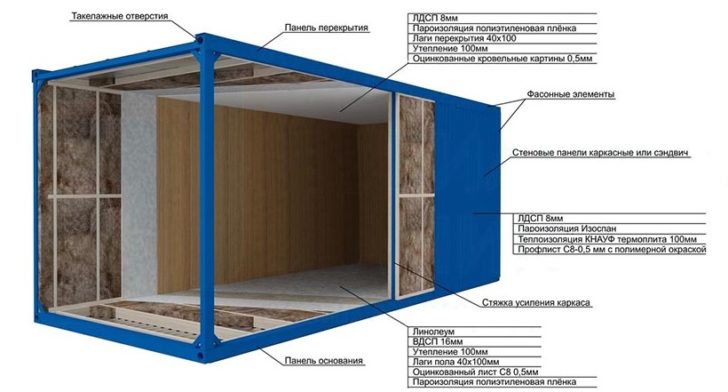

The design of the change house from sandwich panels

The base for the building, due to the minimum weight, can be any available. Suitable and practically equivalent options with slab, tape, columnar and even screw pile foundations.The main thing is to observe the following condition: the lower edge of the wall sandwich panels must rest on a solid solid base. It is strictly mandatory to comply with this rule when building a stationary change house with the possibility of people living in it.

The foundation for a change house from sandwich panels can be any available

Assembly of a change house

After the base is installed, a frame for mounting panels is assembled on it - its layout and dimensions are indicated in the manual attached to the change house. The dimensions and level should be observed as accurately as possible - otherwise the assembly work can be very complicated. Do not neglect the transverse stiffeners, especially in window and door openings.

With minimal experience, the necessary tools and a responsible approach, do-it-yourself installation of a summer house from scratch and under the roof takes only a few hours. Given that when assembling the frame, the detachable connections included in the kit are used, the change house turns out to be collapsible and, accordingly, transportable. When it is no longer needed, it can be stored unassembled.

The change house from a sandwich panels turns out collapsible and transportable

The installation of sandwich panels begins with the floor elements, then the wall elements are attached, then the roof elements. Lastly, the ceiling parts are mounted. Then window-doors are installed, if necessary, electrical wiring is “scattered”. When planning a stay in a change house in the winter, it is necessary to provide additional insulation in it or install a heating system of a suitable type.

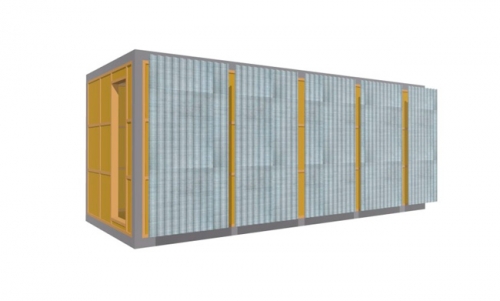

back to index ↑container change house

Making a do-it-yourself container-type change house for a person with experience in welding does not present any particular difficulties. Technologically, its design is extremely simple - a metal frame sheathed with sheet profiled iron. The main disadvantage of such buildings is that they are non-separable and, accordingly, completely stationary.

Construction of a container house

Let's take a look at how to make a country change house with your own hands according to step-by-step instructions.

Preparation and installation of the base

For such a structure, just like for the previous ones, a prepared site with a minimum foundation is required, for which any of the above is suitable. On the foundation along the perimeter of the future building of profiled metal (corner, channel, pipes of rectangular section), a rectangular base is welded under the frame of the change house. Vertical metal racks are welded in the corners, from above they are connected by horizontal jumpers.

Rectangular base and frame

Final assembly

After the manufacture of this minimalistic “box”, openings for windows and doors are made and welded. Then the walls are sheathed with profiled sheet. From the inside, the frame, if necessary, is insulated, sheets of OSB, chipboard and other any suitable material are sewn on top. You can, of course, use siding panels - but this will significantly lengthen the installation time.

Wall cladding with profiled sheet

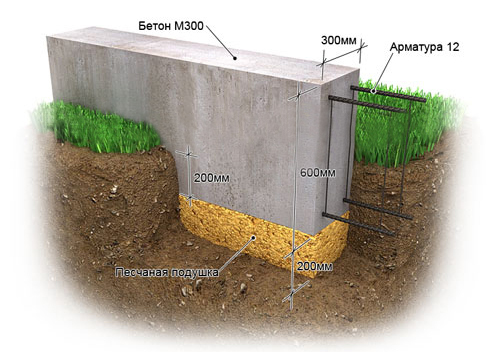

Log cabins

Change houses made of logs or wooden beams look very impressive, they are durable and relatively warm, but their construction is very expensive. As a temporary structure, they are not suitable categorically.

The foundation in the form of a slab is used extremely rarely for them - a light tape base is traditionally arranged. When building a change house on rocky ground, four boards 200x50 mm may well play the role of a foundation.

Lightweight tape base for a change house

The main rule when building such change houses with your own hands is the obligatory coating of all wooden parts and elements with antiseptic materials, otherwise the wood will quickly rot and turn black. In addition, one should not forget about the rather long time required for the shrinkage of log cabins.

It takes time to shrink log cabins

Do-it-yourself change house 3 by 3: estimate

It is not uncommon for a change house to be built with the prospect of using it as a summer kitchen, a guest house, or even just a barn - in general, a building on the farm is necessary and even necessary. However, to take on the construction of a 3 by 3 change house with your own hands, without presenting at least an approximate estimate of the upcoming costs, is at least reckless!

What determines the price

The cost of future work and the cost of materials depends on a large number of factors, the main of which are the following:

- type and dimensions of the foundation;

- the dimensions of the change house itself;

- building wall material;

- availability and quality of interior decoration;

- floor and roof construction;

- number, size and design of windows and doors;

- the presence and scale of engineering communications in the change house - electrical wiring, water supply, sewerage.

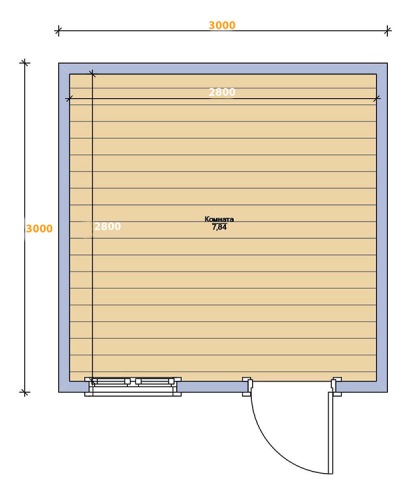

The project of a change house with an area of 3x3 m

To make it easier to take into account all these points, it is necessary to draw up a project, having decided on the size of the future premises; and the dimensions are dictated by the planned functional "duties" of the change house. The change house with an area of 3x3 m is quite enough for use as a tool storage, a summer kitchen and a mini-bedroom with a single bed.

Invisible expenses

The optimal material for construction is wood; This is due to its low cost and reusability. Metal is significantly more expensive and requires certain professional skills during construction - but if they are available, construction takes much less time.

The presence of windows, at least the smallest ones, is mandatory in a change house - even if they do not play their direct role, they will definitely come in handy to ensure air ventilation. It is highly desirable to have an existing electrical wiring in the change house - at least one outlet and artificial lighting will not be superfluous.

Wood is the best building material

If you want to entrust rather dirty construction work to professionals from construction companies, it’s a good idea to first familiarize yourself with the cost of their services - sometimes it can be quite unexpected. But in any case, the total amount in the estimate for the construction of a 3 by 3 change house with your own hands will always be less.

A little about the choice of materials

Wooden structures do not require special professional skills from the performer, but this material needs high-quality antiseptic treatment - otherwise it will last only a few seasons. And such processing is a rather expensive pleasure. If it is necessary to carry out finishing work and if the building has a vestibule, the cost of materials can be safely multiplied by one and a half, and preferably by two.

Wood needs high-quality antiseptic treatment

Metal structures are much more durable than wooden structures, but also more expensive. But their main drawback is that they are relatively difficult to make collapsible and mobile. Other things being equal - the same finish, communications, areas - metal structures cost about one and a half times more than wooden ones.

Unexpected expenses

Another often forgotten, but quite serious and in many cases practically unpredictable do-it-yourself 3 by 3 do-it-yourself change house estimate article is “consumables”. These include staples for a stapler, adhesive tape, nails and self-tapping screws, electrodes, wind and vapor barrier film, insulation.

You can somewhat reduce costs if you hire professional builders, but buy the material yourself. However, in this case, you need to be well versed in the characteristics of modern building materials, otherwise the savings can be very ephemeral.

back to index ↑Do-it-yourself trailer

Using old metal trailers for a change house is an old folk tradition. If possible, buying such a ready-made trailer is a very convenient option, allowing you to practically not think about the construction and interior decoration of the premises. They are relatively inexpensive, even taking into account shipping and loading and unloading.

You can buy a ready-made trailer

The interior of the change house trailer is easy to do with your own hands. They can be both combined and separate, but the presence of a vestibule is highly desirable - in the cold season it will prevent the penetration of cold air into the premises.

Area

A foundation for such a change house is not required - a cleared and leveled area is enough. Such trailers are installed on a metal frame or small concrete blocks. The main thing is that the bottom of the trailer should not be located directly on the ground, and there should be a gap of 20-30 cm.

The foundation for the change house trailer is not required

frame

As a frame on which a do-it-yourself trailer-change house will be installed, you can use the elements of a metal cargo container. In the absence of such an opportunity, the frame can be constructed from wooden bars with a section of at least 50x50 mm.

Sheathing and floors

After installing the trailer on the frame, it is necessary to mark on it the location of windows (if there are no ready-made ones) and doors. If necessary, it is possible to build a gable roof over the change house from metal tiles or sheet "galvanization". You can arrange a new floor in the change house trailer with your own hands - lay logs, insulate the space between them and lay a finishing coating (boards, OSB or plywood).

Before laying the finishing floor, it is necessary, again - if necessary, to carry out work on sheathing the outer walls of the trailer. The material used is the one that is available - sandwich, OSB panels, sheet iron, boards. Similar operations are carried out with the internal walls of the change house. Lastly, windows and communications are mounted.

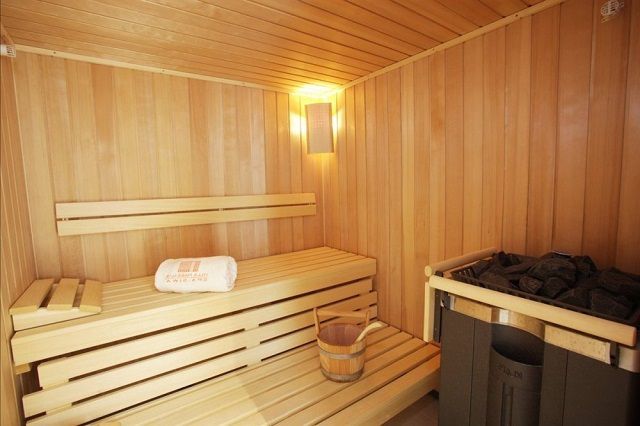

back to index ↑Do-it-yourself bath from a change house

“The outer covering of the walls of a bathhouse made from a do-it-yourself change house must be windproof, for example, from OSB panels”

A change house on a personal plot is, in fact, a “semi-finished product” of a bath. However, in order to turn it into a full-fledged bath, one cannot do without small preparatory construction operations.

So, in order to make a bath from a change house with your own hands, you will need:

- dismantle the decorative lining of the internal walls of the change house;

- make a complete and high-quality waterproofing of the entire structure;

- make reliable thermal insulation of the room;

- bring communications; as a minimum, provide sewer water drainage;

- ensure natural ventilation of the underground space - for this, the change house must be raised at least 30 cm from the ground.

Do-it-yourself bath scheme from a change house

The best material for do-it-yourself waterproofing of a bathhouse from a change house is a polymer hydrobarrier. Thermal insulation is best done with polystyrene sheets or special mats, not forgetting about vapor barrier; moreover, it is better to lay thermal insulation both on the inside and on the outside of the walls of the building.

Polymer hydrobarrier - the best material for waterproofing

The ideal material for interior wall decoration is a wooden "lining". A more beautiful, but also very expensive option is to sheath the internal walls with waterproof drywall, lined with ceramic tiles on top. A combination of these two finishing methods is also not forbidden. The outer covering of the walls of the bath from a do-it-yourself change house must be windproof, for example, from OSB panels.

Lining - the best material for interior wall decoration

Conclusion

There are countless possible designs for building a backyard change house with your own hands, since almost any available material can be used.

The main thing is to follow the technology and the procedure for performing construction operations and do not forget that a deviation in order to save money from the norms tested over the years may well lead to a very strong increase in the cost of construction.

Photo gallery - do-it-yourself change house

Video