An attic under a pitched roof is usually used as a utility room. Sometimes it is commensurate in size with a small attic, but the fundamental difference is that the attic is intended for seasonal or year-round use, and, accordingly, the stairs leading to it are used several times a day. And the need to go up to the attic arises no more than twice a week (for example, for brooms on a bath day), and usually even less often.

How to get into the attic? If such a need arises once or twice a year, then you can use a ladder from the street, but this is extremely inconvenient, dangerous and generally not suitable for everyone.

For some time, at the stage of construction and arrangement, one has to put up with such an inconvenience, but there comes a moment when the hands reach the device of a normal attic staircase and questions arise - how to make the ascent and descent safe and how to ensure the thermal insulation of the hatch if the attic is unheated?

Sometimes a spacious attic is insulated and turned into a small attic, equipping a children's room, a workshop or an office there, but is it convenient to climb into it?

Consider what stairs the industry offers, and what you can do with your own hands. In this article, we will pay special attention to stairs with a hatch - we will consider the features of their design, disadvantages and advantages, how easy it is to use them and what you need to know about installation.

Stair types

A mandatory element of the entrance to the attic from the main room is a hatch, its design will be discussed below and in great detail. Stairs leading to the hatch can be:

- Portable.

- Stationary.

- Folding industrial.

- Folding simplified.

Each option deserves consideration. You can’t reject budget options at the start or those that seem too complicated and expensive: they all have certain advantages and price gaps.

Portable loft ladders

If the owners visit the attic once a year and are limited in funds, then the choice is obvious - it is enough to arrange a tightly closing hatch and store a ladder or ladder of the required length nearby. Safety is slightly increased if you fill (stick) non-slip pads on the legs. Some ladders and ladders are equipped with handrails. If the hatch is cut close to the wall, the handrail can be nailed directly to the wall. That's it, you can't imagine any more "conveniences" here.

In residential buildings, ladders are usually not used, it is not safe, but they help out in the country, sauna or outbuildings.

Stationary stairs to the attic

If the dimensions of the room allow you to place a stationary marching or spiral attic staircase with a hatch, then this is the most solid and safe option. It is not a fact that it will turn out to be more expensive than a folding one: its price depends on the design, materials, finishes and decor, but still usually - yes, it turns out to be more expensive.

“A stationary attic ladder of the simplest design, made by oneself, will cost less than a folding one, but, unfortunately, it reduces the usable area, and the area of \u200b\u200bthe house has its price.”

In order not to clutter up the room, the mid-flight stairs to the attic are made with a steep slope, so sometimes you have to use an asymmetric design of steps - the so-called "goose step".

It is believed that the distance between the steps should not exceed 20 cm, the number of crossbars - no more than 15, and the slope is chosen in the range of 40-60 degrees. A large slope is also dictated by the size of the hatch - when entering the attic through a hatch 70-120 cm long and with a slope of 20-35 degrees, the head will hit the ceiling - you will need to make the hatch too large.

A spiral attic staircase, metal or wooden, occupies a larger area than a mid-flight staircase, but it is more compact in the sense that it does not cross the room.

Folding industrial ladders

A sliding wooden or metal staircase is integral with the hatch. When folded, it is hidden at the top, above the hatch cover, which has a very aesthetic appearance and does not disfigure the ceiling. When opening the hatch, it becomes possible to push it and fix it.

The material, profile, and span unfolding system varies:

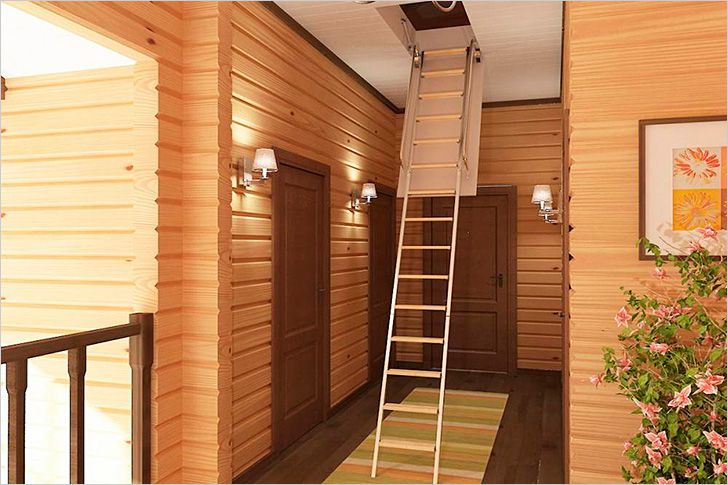

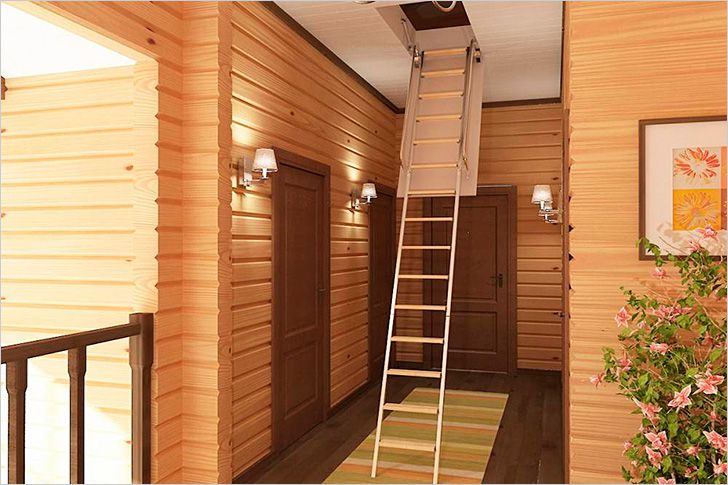

- Wooden or metal sliding stairs - two or three sections that extend parallel to each other, forming a smooth ladder.

- Wooden or metal folding ladder - two or more sections are folded like an accordion.

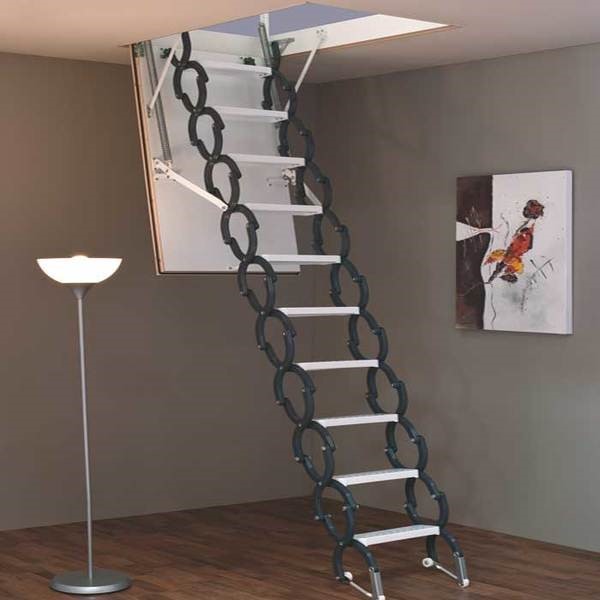

- Metal folding scissor type (such a mechanism is also called parallelogram).

- Metal scissor type with a spring mechanism.

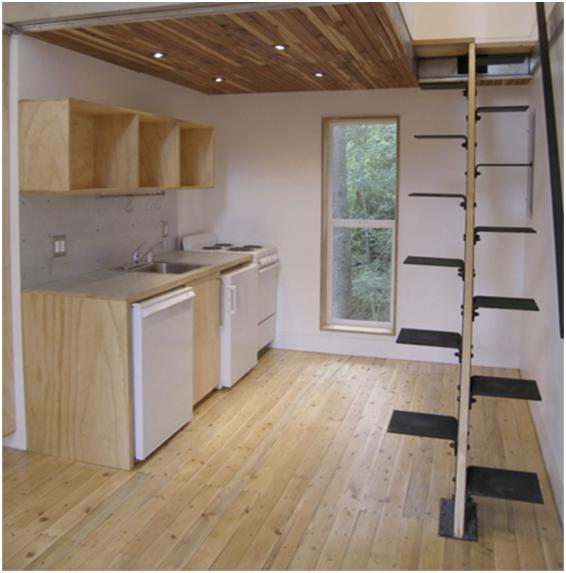

- Metal tubular retractable telescopic.

The sliding design is inferior to the stationary one in comfort, but the overall design of the room greatly benefits. It is very important that space is saved - there is simply no ladder when folded.

The safety of industrial designs is guaranteed by manufacturers - they provide handrails, achieve the necessary rigidity and design products for standard or increased user weight.

It is convenient that manufacturers supply attic stairs with a hatch. No need to think about its design, insulation and locking system - the insulated attic hatch with a ladder is delivered on a turnkey basis or in a complete set, with detailed assembly instructions. There are also models for a warm attic that do not have thermal insulation on the manhole cover.

Simplified folding stairs "do it yourself"

These loft ladders occupy an intermediate position between industrial and portable ones. They are not attached to the hatch, but to the wall, and usually fold in half. When folded, they are attached to the wall.

The advantage of simplified folding ladders over portable ones is that they are assigned a certain place, they cannot be carried away, they are not lost. In addition, they are securely fixed at the top, which increases safety.

The advantage over stationary ones is that they do not get underfoot. The disadvantage of simplified stairs is that they cannot be said to decorate the interior.

Choice of materials: strength, lightness, authenticity

The design uses wood, aluminum, steel and plastic.

The choice of materials for a folding attic ladder with a hatch is based on the ratio of strength and lightness of the structure - nevertheless, it has to be raised and lowered manually, if a spring mechanism or an electric drive is not provided.

The most durable ladders are made of steel or thick aluminum profiles and are designed for weights over 150 kg (the weight of a large man with a load). To make it convenient for all family members to use them, it is advisable to provide a spring-loaded lifting mechanism.

The lightest attic stairs with a hatch are aluminum. Sometimes they have plastic parts: handrails or overlays on steps. The weight of wooden ones depends on the wood used, for example, birch is lighter than pine.

Heavy ladders include scissor extension ladders and steel telescopic ladders. Aluminum telescopic ones are considered less reliable than steel ones - due to the increased gap between the pipes, play is felt, but they are much lighter and cheaper.

The second criterion is style. If the interior of the house is designed in country or ethnic style, then the aluminum staircase will bring dissonance into it. Hidden behind the hatch, it will not be conspicuous, but with equal characteristics, it makes sense to consider a wooden structure.

Accordingly, a simplified wooden folding ladder will look strange in high-tech style, but a metal telescopic ladder is fully consistent with the design concept.

“Loft-style interior lovers should pay attention to attic scissor-type stairs, which are made of steel and sometimes have expressive blackening and a rare curved profile. It would even be a pity to hide such a staircase - it complements the surroundings of the loft so picturesquely.

When comparing metal and wood, it should be taken into account that the wooden structure does not rattle when extended and folded out, like metal - for some buyers this matters.

The price depends on many factors, including the lifting mechanism.

Description of stairs made of different materials:

- Wooden. Guides (string) and steps made of wood, fasteners made of aluminum and steel.

- Aluminum. Bowstring and steps made of duralumin profile. Sometimes lighter alloys (silumin) and plastic elements are used.

- Steel scissors. Scissor folding sections do not have a bowstring in the traditional view, its function is performed by a scissor mechanism to which the steps are attached.

- Steel or aluminum telescopic. In telescopic attic stairs, the steps are attached to pipe sections, which, when unfolded, form a tubular bowstring, the diameter of which gradually decreases from bottom to top.

hatch design requirements

The hatch can be insulated or not insulated - it depends on the insulation of the attic. The exit to the warm floor does not need to be insulated, and the hatch overlooking the cold attic requires the same insulation as the ceiling. Finished hatches have a layer of expanded polystyrene and are marked with the "Thermo" marking.

Attic stairs with a hatch - dimensions

The size of the hatch is chosen based on the needs. The steeper the angle of inclination of the stairs, the shorter the hatch can be made. The width depends on the dimensions of the residents and the area allotted for the stairs.

The industry offers narrow hatches, size in mm:

- 510x800;

- 600x600;

- 600x900;

- 600x1200

.Wide hatches, mm:

- 700x800;

- 700x1200.

When choosing the size of the attic staircase hatch and determining the installation location, it is desirable to take into account the pitch of the floor beams so that the supporting structure does not have to be weakened due to the insertion of an attic hatch that is too wide or too long.

Location of hatch

The insertion point is chosen between the floor beams - so as to leave a distance of 10 mm to the beams. The attic ladder in the unfolded state should not completely block the passage, rest against the wall or go to the stationary ladder.

Installation of a finished attic staircase with a hatch

The complete set of an industrial attic ladder with a hatch includes all the necessary fasteners and installation instructions.

The longest time will be to mount the accordion or sliding structure if it is not supplied assembled. It is easier to install a scissor or telescopic mechanism - it is always supplied assembled and installation is reduced to fixing it on the hatch cover and installing the hatch in the opening.

There are a few points that you will have to deal with during installation - and although they are also covered in the instructions, it is better to be prepared in advance.

Floor preparation

Depending on what kind of flooring is in the house - concrete or wood - the tie-in has its own characteristics. If the hatch is part of the project, a hole in the ceiling is foreseen for it in advance, and there are no further problems. If the arrangement of access to the attic occurs as part of the reconstruction, it is required to conduct an examination of the ceiling.

Wood floor:

- Determine where the beams go. It is easier to find out from the side of the attic, fixing the flooring or by tapping. In a log home, the ends of the beams are usually visible from the outside.

- If the beam interferes with the installation of the hatch, it is cut out in the desired area, but unfastened with crossbars.

- The place of the opening is fixed with boards on steel corners.

- Prepare and fix the frame of the required size and thickness - taking into account the fact that the hatch may protrude above the level of the attic floor.

Concrete floor:

- The hole is cut to the size of the frame using a grinder.

- Fasten the frame in the cut out opening.

Hatch installation

According to the instructions, the dimensions of the opening must exactly match the external dimensions of the hatch. In practice, to improve the appearance of the ceiling, it is allowed to leave the decorative ceiling sheathing fabric protruding inward by 3-5 cm, to the state “close to the hatch cover”. This may be necessary to make it as invisible as possible, not to emphasize the edges with trim.

Aligning the sunroof and ceiling in a single plane is easy if the manufacturer has completed the set with adjustable mounting brackets. In this case, the hatch is suspended from the side of the attic and lowered flush with the ceiling with screws.

If there are no screw brackets in the kit, then from the side of the room, two rails are attached to the ceiling across the opening, on which the block is laid and then fixed in the ceiling opening. After removing the rails, the holes are overwritten - but cosmetic repairs after installing the hatch are still almost inevitable.

It is advisable to strengthen the door along the perimeter with a finishing rail - it will not only close the gaps, but also protect the edges of the hatch from damage.

span assembly

If the ladder is supplied in a do-it-yourself format, which is more common with wooden attic stairs, the main thing to remember is not to use hardened screws, but only the mild steel screws and anodized dowels that come with the kit.

Warming

The space between the block and the opening is best filled with mounting foam. We are talking not only about a cold attic, for which foaming is a mandatory operation, but also about a warm one. Foam will give the structure additional stability.

Ladder Length Adjustment

“The length of the ladder should be slightly longer than necessary in order to accurately fit it in size. It should rest firmly on the floor and not bend at the same time. If the flooring on the floor is not yet ready, the fitting of the stairs is carried out after the flooring.

Wooden and aluminum bowstrings are sawn to the desired length. In a scissor steel structure, one or more elements are removed. For telescopic ladders, adjustment is not necessary - some excess length is eliminated by incomplete opening of the lower steps, and this does not affect the rigidity of the structure. However, the lower step is doubled, thickened, so the pipe is either filed or one or two segments are removed.

"All by myself!" Appeal to the restless and skilled

If the reader is fired up to make the entire structure on his own, then this is possible. But you need to understand what pushes him to this decision.

If the question of price arose, then a non-specialist will not be able to save much. Of course, materials and fasteners will cost much less than a complete set, but if you spend time on the main income, then the money is just enough for a finished industrial version. Or not enough.Or more than enough free time. Or you just want to warm up and prove. Then, of course, nothing is impossible.

Such trifles (although a well-maintained entrance to the attic is, of course, not a trifle!) - and so, everything that is done with one's own hands is more expensive than purchased. Options - a lot.

You can make an insulated attic hatch with a stationary type ladder. Yes, it is not necessary to resort to a complex folding structure if the area and layout of the house allow you to make a full-fledged flight of stairs. By the way, even a simplified folding or portable ladder can be turned into an artifact that emphasizes the individuality of the home.

“A home-made attic staircase with a hatch will surely differ in exclusive performance and perfectly match the master’s plan, and this is priceless.”

Photo gallery